When it comes to maintaining engine performance, the crankshaft is the most important component. Found in marine vessels, power plants, and heavy machinery, it’s a crucial part of the engine. But when it gets damaged or worn out, it can bring operations to a screeching halt, leading to expensive repairs and downtime. Traditionally, fixing a crankshaft meant removing it entirely— a process that’s time-consuming, costly, and a logistical headache. RA Power Solutions is a global leader in crankshaft repair, which has brought its revolutionary in situ crankshaft grinding technology to Bangladesh. This innovative solution is changing the game for industries across the country.

What is In Situ Crankshaft Grinding?

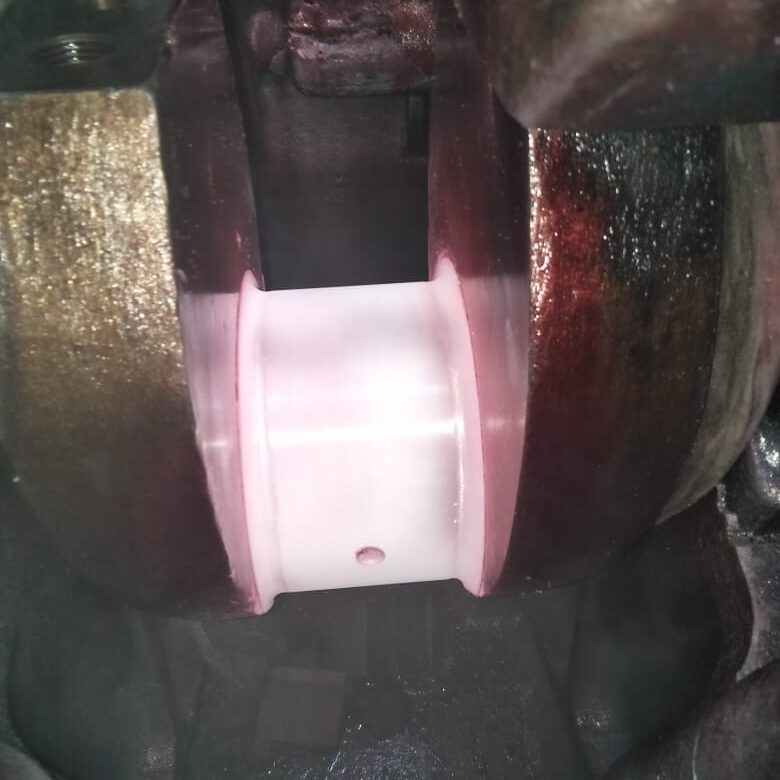

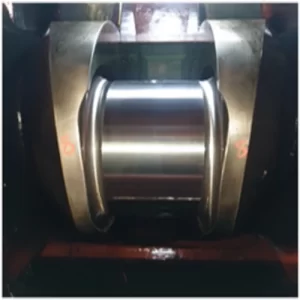

In simple terms, in situ crankshaft grinding is a way to repair crankshafts without taking them out of the engine. Instead of dismantling the entire machine and sending the crankshaft to a workshop, the repair is done right where the equipment is located. Using specialized portable grinding machines, technicians can restore the crankshaft’s journals (the smooth, polished surfaces that connect to other engine parts) to their original size and finish. This ensures the engine runs smoothly and extends its lifespan, all without the hassle of removal.

Why RA Power Solutions Stands Out

RA Power Solutions is a trusted name in the world of crankshaft repair, with 4 decades of experience and a reputation for excellence. The company has brought its expertise to Bangladesh, offering in situ crankshaft grinding services to industries like shipping, power generation, and manufacturing. Their team of skilled technicians uses advanced crankshaft grinding machines to deliver repairs that meet or exceed OEM (Original Equipment Manufacturer) standards. This is especially valuable in Bangladesh, where industries often face logistical challenges and need quick, cost-effective solutions to keep operations running.

The Benefits of In Situ Crankshaft Grinding:

- Less Downtime, More Productivity:

Since the crankshaft doesn’t need to be removed, repairs are completed much faster. This means less downtime for businesses and more time for productivity.

- Precision Repairs:

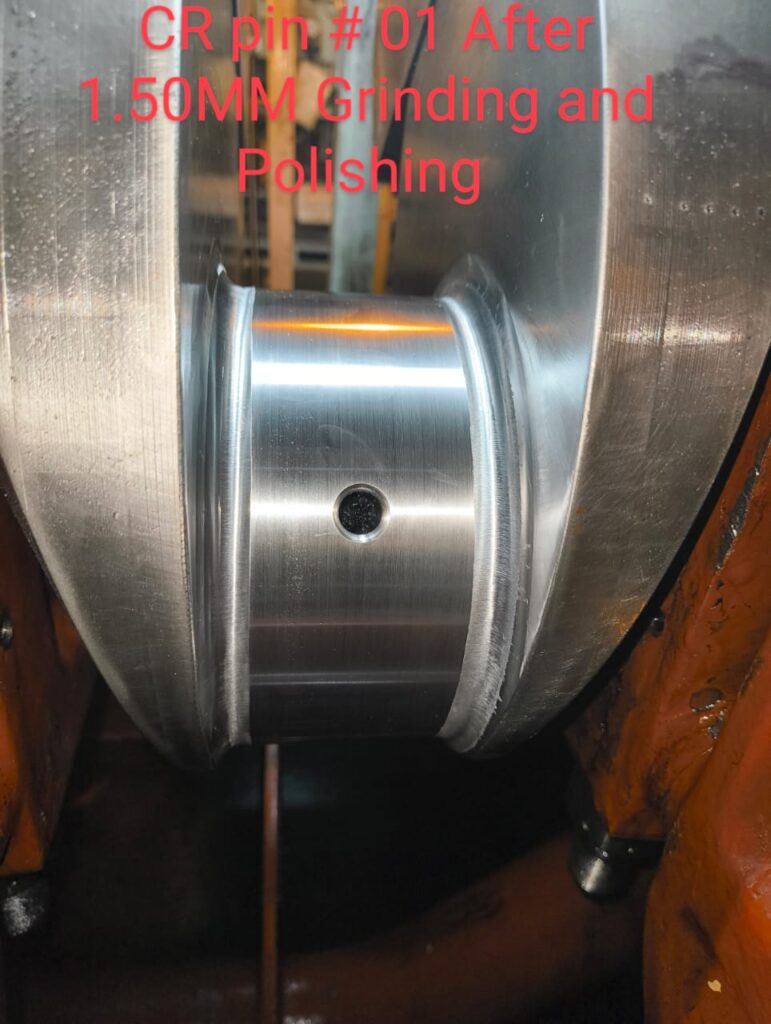

RA Power Solutions uses cutting-edge technology to ensure the crankshaft is restored to its original specifications. This precision ensures the engine performs at its best and lasts longer.

- On-Site Convenience:

Whether it’s a remote power plant or a ship docked at a port. RA Power Solutions can bring its portable grinding machines to the site. This flexibility is a huge advantage for industries in hard-to-reach locations.

One standout example of RA Power Solutions’ impact in Bangladesh is their work with a major power plant. The plant’s crankshaft had worn down over the years of use, threatening to shut down power generation. Instead of going through the lengthy and expensive process of removing the crankshaft. RA Power Solutions’ team performed in situ grinding onsite. They restored the crankshaft to its original condition, ensuring the plant could continue operating without interruption. This not only saved the plant from costly downtime but also demonstrated the effectiveness of in situ grinding in real-world scenarios.

As industries in Bangladesh continue to grow, the demand for efficient and reliable maintenance solutions is on the rise. In situ crankshaft grinding is perfectly positioned to meet this demand. RA Power Solutions, with its advanced technology and experienced team, is leading the charge. By adopting this innovative technique, businesses in Bangladesh can reduce repair costs, minimize downtime, and keep their operations running smoothly.

For more information regarding insitu crankshaft grinding and repair, in situ crankshaft grinding, onsite services, and crankshaft grinding and repair in Bangladesh, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

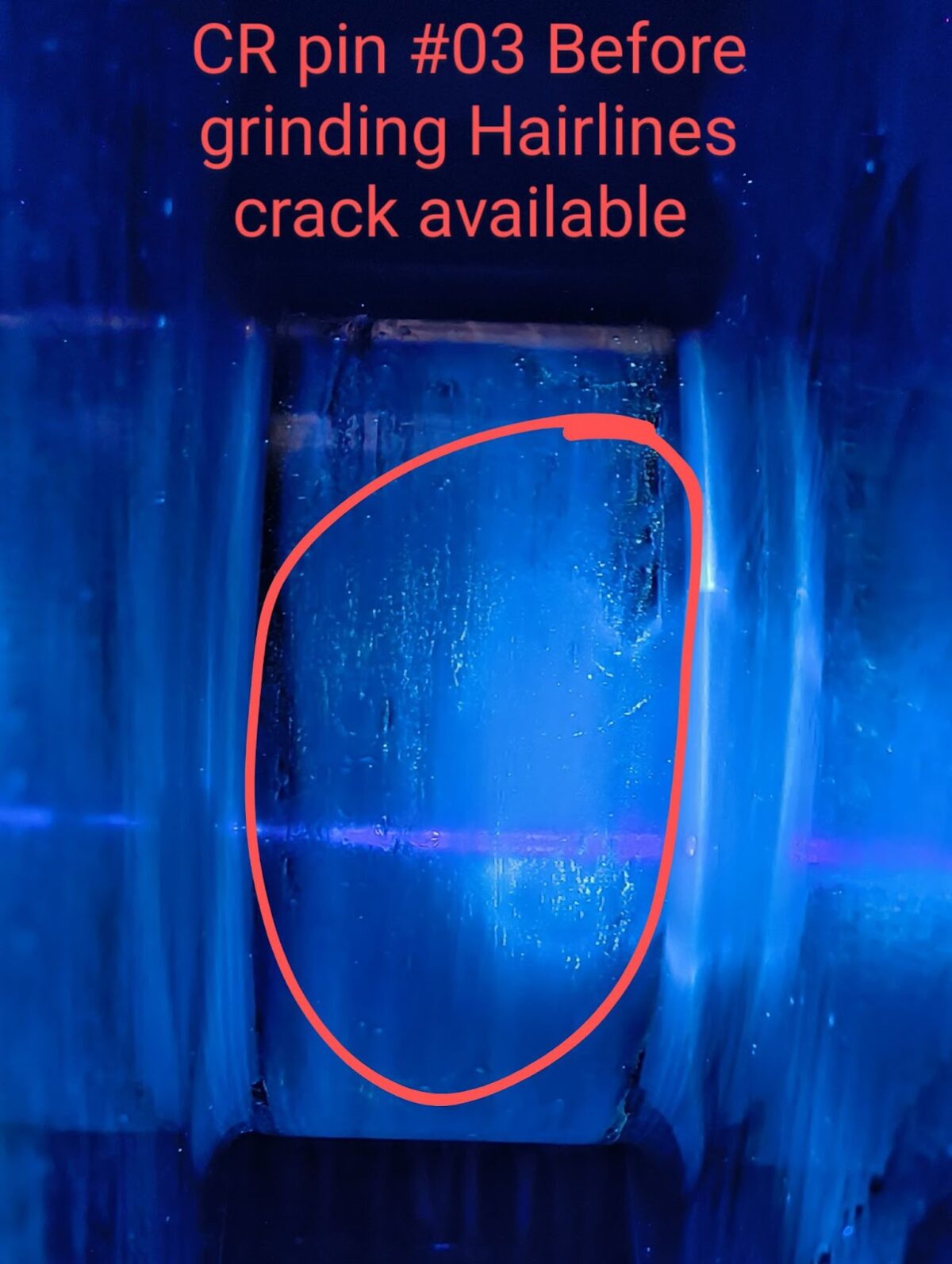

We strongly suggest that medium and high-capacity compressors that their crankshafts should be periodically calibrated for taper and ovality, rough surface, hardness, and crack detection.

We strongly suggest that medium and high-capacity compressors that their crankshafts should be periodically calibrated for taper and ovality, rough surface, hardness, and crack detection.