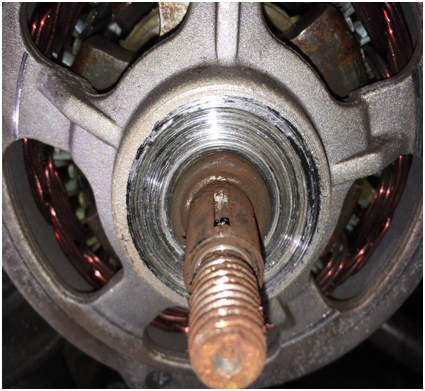

It is observed that in power plants and heavy industries, the turbine shafts, alternator shafts, rotor shafts, pumps, crankshafts operate continuously without any break. The babbitt white metal bearings which support the shafts get worn out due to continuous operation or get damaged due to an accident.

We have observed that while the white metal bearing are promptly replaced, but no action is taken on the shaft which is supported by the bearings.

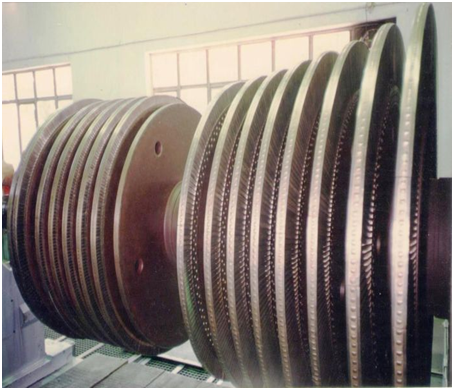

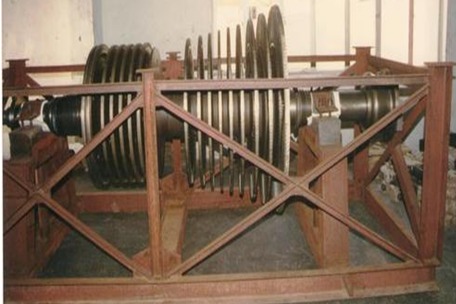

RA Power Solutions have introduced a revolutionary onsite polishing machine details of which are given below:-

- Enhance the life of the turbine shafts, alternator shafts, rotor shafts, pumps, crankshafts by onsite polishing.

- As mentioned above, the damaged or old worn-out bearings are replaced, but no attention is given to the shaft. We offer the comprehensive services and annual contract of polishing of the shafts installed in your factory.

The details of polishing are as following:-

- We depute a team of technicians who are experienced to undertake dimensional inspection of the shaft to check the taper and ovality. The inspection is done by the calibrated instruments.

- The hardness of the shaft and crack detection by MPI is undertaken. This is required only in case of accidents.

- The surface finish of the bearing sitting area of the shaft is checked. We use an advanced mitutoyo surface finish instrument to check.

- Visual inspection is undertaken to check the pitting, bearing line marks, etc.

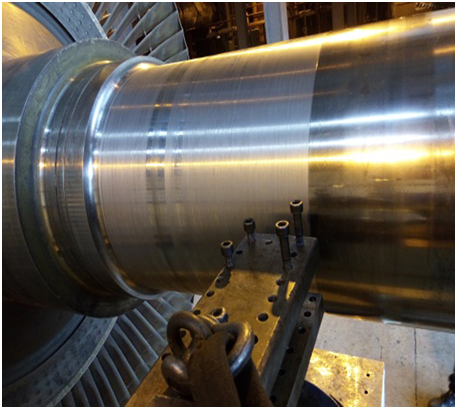

Use of onsite polishing equipment

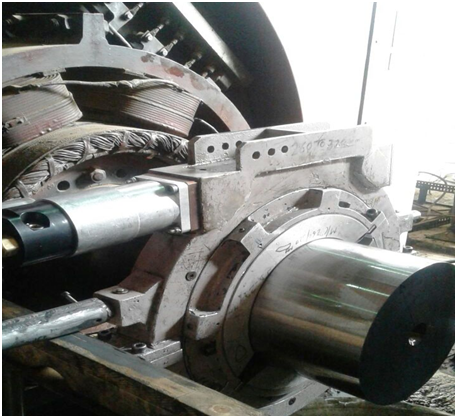

We have portable onsite polishing equipment which is carried by technicians to any site all over the world. This revolutionary onsite polishing equipment is capable of removing high points, bearing line marks, pitting. The stock removal can be as low as 0.01 mm, thus there is no change in the oil gap and dimension of shaft.

Increase the life of turbine shafts, alternator shafts, rotor shafts, pumps, crankshafts

Our clients all over the world have experienced that by polishing the shafts prior to fitment of white metal babbitt bearing increases not only the life of bearings but also of the shaft. It avoids major breakdown of the shaft, bearing and the plant.

NO REQUIREMENT OF REMOVAL OF THE SHAFT FROM THE MAIN EQUIPMENT

It is possible to undertake the polishing of the shaft without any disassembly, hence minimum downtime and high surface finish can be achieved onsite.

LOW COST OF POLISHING

The cost of polishing on site is marginal in comparison to the damage caused to the bearing and the shaft in the long term. It’s a technology which is now easily available and the advantage of which power plants, industries, shipping companies can take wherever the rotary equipments are used.

We are available 24*7 to serve you :

This article or blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy, and Shipping industries. He is Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professional, and he has all the brilliance of an exemplary leader. Mr. Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information regarding onsite and crankshaft polishing machine, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.