In situ crankshaft grinding machine is an ideal solution for repair of a damaged crank pin journal of diesel engine without dismantling of the crankshaft.

Benefits of In-Situ Grinding Machine:-

RA Power Solutions grinding technology and tools are not only user-friendly, but are also capable of grinding the crankshaft to close dimensional and with geometric tolerance. These grinding tools are portable and can be easily carried by technicians to the site.

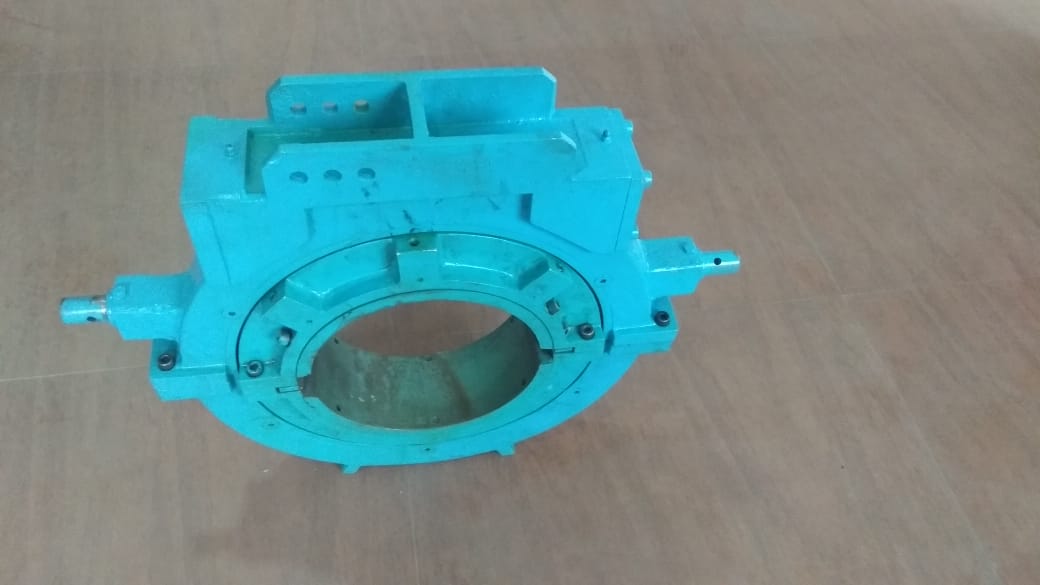

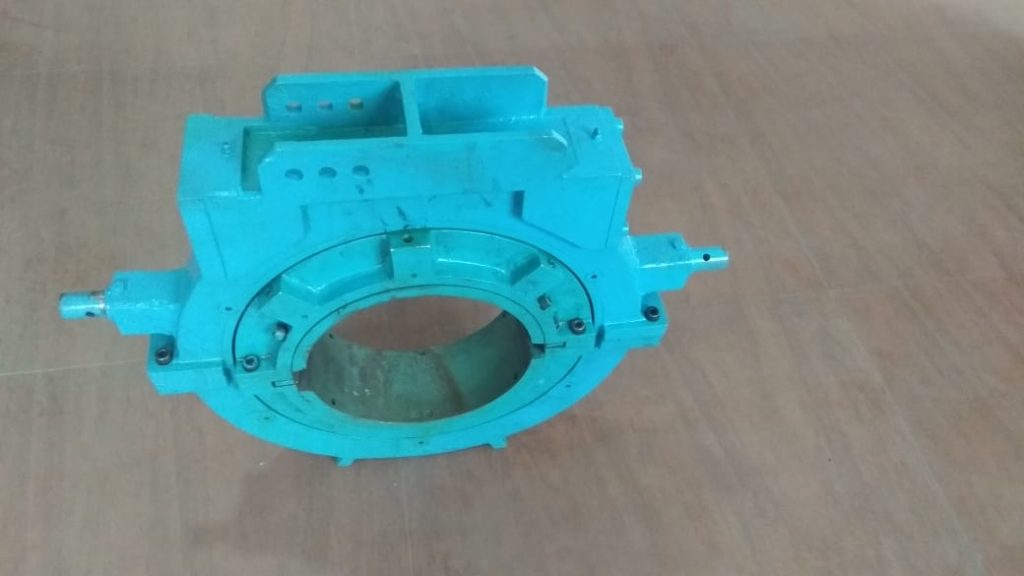

Main Accessories of In-Situ Grinding Machine supplied by RA Power Solutions:

- In situ grinding machine (Complete Set)

- Mother Bush

- Bush

- Pneumatic Motor with Adapter

- Hand valve

- Hose Pipe

- Hanging Pipe (G.I)

- Pneumatic Hand Grinder

- Mops, Mounting Wheel & Rubber Base Wheel

- Consumables and grinding media

- Tool Box (Complete Set)

The measuring instrument used in the Job of grinding and polishing of crankshaft:-

- Micrometer (Depend on Crankshaft Crank pin and main journal Diameter)

- Micrometer 0-25 mm outside Ball Type Micrometer

- Inside micrometer or bore gauge

- Hardness Tester

- Deflection Gauge

- Magnetic Dial Stand with Dial Gauge

- DP Test Kit or MPI Test Machine

- Radius Gauge

- Filler Gauge

Instructions for using on site crankshaft and cylindrical Grinding Machine:-

Inspection:

- Check CR Pin Size, Hardness, DP Test, or Magnetic Particle Test and

- Deflection, in case all reports are good after that, take Second Step.

- Dismantle the machine and check all spare parts, assemble the Pneumatic Motor in insitu grinding machine.

- Assemble the hardware in the shell and assemble the machine on the crank pin and rotate gear manually.

- Assemble the machine upper and lower cap and recheck all bolts.

- Connect Air Hose Pipe to Pneumatic Motor.

- After machining process first round is complete, dismantle the in situ grinding machine and check size of Crank Pin.

- Follow same step to complete job.

- Before maintaining final size, check hardness, MPI or DP Test & take Maximum Reading by Micrometer.

Note: Before final size check, reset outside micrometer and take dimension again.

Maintenance & Cleaning:-

In order to properly maintain machine tool, it is very important to perform maintenance checks periodically of all accessories. The author is Mr. Raj Shahani, Managing Director of the company. He is having forty years of experience in providing onsite engine repair services to companies all over the world. After extensive research and field trials, he has developed in situ crankshaft grinding and polishing machine to make the repair process easy and cost-effective.

For any information on crankpin repair, in situ crankshaft grinding please feel free to write to us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.