We are the manufacturer and trader of Tri metal bearing and Bi metal Bearings used in Diesel engines, compressors & all types of Rotating equipment.

As a marine engine and mechanical equipment repair company serving the industries & shipping companies all over the world for the last 41 years, we understand the importance of the availability of not only the high-quality of Tri-metal and Bi-metal Bearing but the importance of delivery of bearings on time. During our experience of the last four decades, we have observed that although the crankshaft of the marine engine, compressor, or any rotating equipment is repaired due to non-availability of the crankpin & main journal bearing engine cannot be put back into operation thus causing losses to the owner.

The non-availability of engine & compressor bearings may be because the equipment is outdated and no more manufactured by the original equipment manufacturer. There are a number of marine engines, diesel generating sets, and compressors in operation on vessels or industries, the manufacturing of which has been discontinued due to either closure of the manufacturing unit or the equipment has become absolute.

RA Power Solutions plays an important role in the manufacturing of marine engine, white metal bearing repair, diesel generators, compressors, and Rotating equipment bearing Tri-metal and Bi-metal.

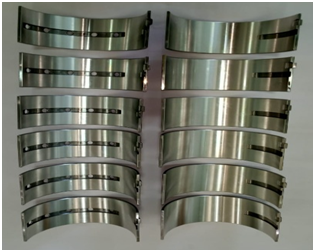

Tri-Metal Bearing and Bi-Metal Bearing Manufacturer

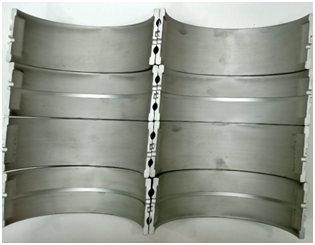

We have the Principles based in the UK, Europe, and Japan from where we source the Tri-Metal Bearing, The Bi metal Bearings and babbitt white metal Bearing up to 1500 mm diameter are manufactured in house.

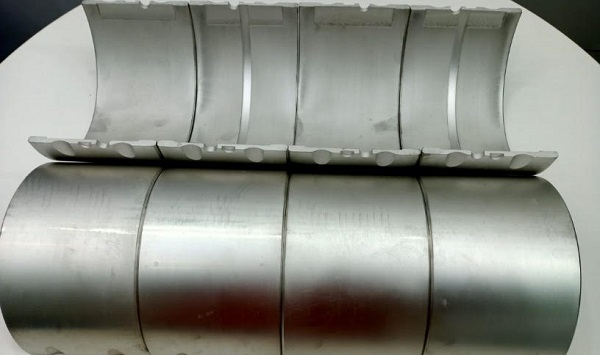

In case your Engine model is old and is no more manufactured by the manufacturer, RA Power Solutions can help you in the development & manufacturing of Tri-metal and Bi metal bearing strictly as per the drawing provided by you. We also develop and manufacture Tri-metal & Bi-metal Bearing as per the sample provided by the client.

Manufacturing of standard and non-standard tri-metal bearings and bi-metal Bearing for marine engine and compressor

As a crankshaft repair company, we have observed that due to serious accidents, the damage to the crankpin/ main journal is much more than the last limit of undersize recommended by the manufacturer. In this case, the engine manufacturer refuses to supply the under-size and oversize bearing.

For example, in case of the last limit of Daihatsu crankpin having a standard diameter of 170 mm and after grinding the size obtained is 167 mm, we manufacture the bearing of 3.0 mm undersize and put the engine back into operation on other hand as per the manufacturer of the engine, the crankshaft cannot be used and is rejected.

We have saved hundreds of crankshafts by supplying undersize Tri-metal Bearing and Bi-metal Bearing beyond the last limit of grinding recommended by the engine manufacturer. We regularly supply engine bearing for crankpin, Tri-metal Bearing, engine tri metal bearing, and Bi-metal Bearing for all make & model of engines like Wartsila, MAK, MAN B&W, Yanmar, Daihatsu, Himsen, Caterpillar, Bergen, Deutz, etc.

We have been regularly exporting the bearings to Bahrain, Bangladesh, Bhutan, Brunei, Burma, Cambodia, East Timor, Georgia, Hong Kong, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Malaysia, Mongolia, Nepal, North Korea, Oman, Papua New Guinea, Philippines, Qatar, etc.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.). Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy, and Shipping industries. He is Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professionals and he has all the brilliance of an exemplary leader. Mr. Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information on tri metal bearing manufacturing company, white metal bearing manufacturer, engine bearing manufacturer, bearings for yanmar engine, bearings for Daihatsu engine, engine tri metal bearings, tri metal bearings contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.