RA Power Solutions Pvt. Ltd. extends repair services for main and auxiliary engines, high-capacity compressors, pumps, and rotating equipment. We have the latest design portable equipment which is carried to the client’s site whether they are land-based power plants or vessels on the move. The services are offered through trained technicians. Being an Indian company having more than 36 years of experience, we are well known for sincerity, on-time services, and the lowest price in this industry. A few of the services offered to us are as under:

Metal Locking and Metal Stitching

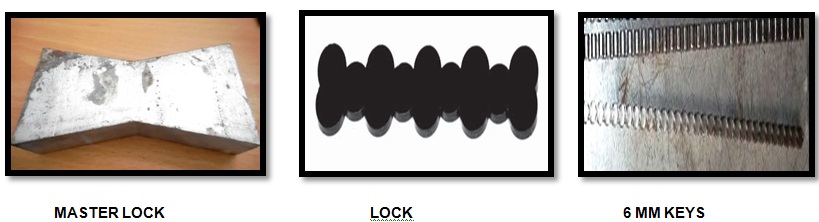

Metal locking and metal stitching is a cold process for repair of steel casting which develops crack or gets broken into pieces due to overload, stress or an accident. RA Power Solutions Pvt. Ltd. has experience of more than 36 years of undertaking repair of most complex accidental damage of plant and machinery, high capacity marine engine, diesel generating sets, engine block, cylinder heads, turbine casing, etc. the repair of casting by metal stitching and metal locking is executed by trained and experienced engineers having experience of more than 40 to 45 years.

The consumables like metal locks and metal keys are procured from reputed companies based in USA and UK. We are cost-effective and can depute our team of technicians within 6 hours notice.

We are experts in the repair of crankshaft of high-capacity marine engines upto 700 mm diameter, diesel generating sets, and other applications. The services are extended all over the world through our experienced technicians.

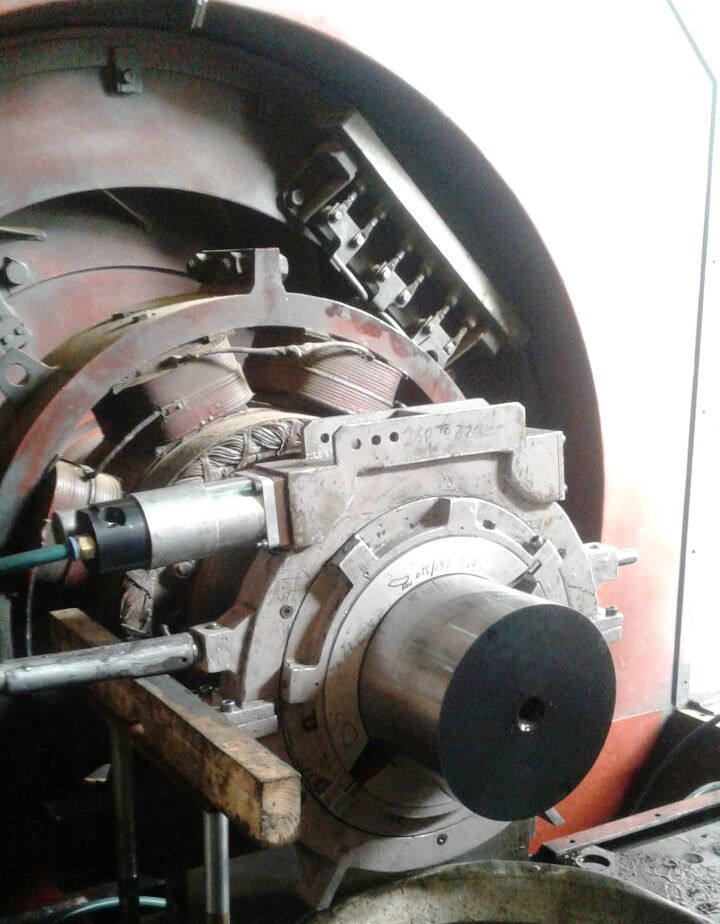

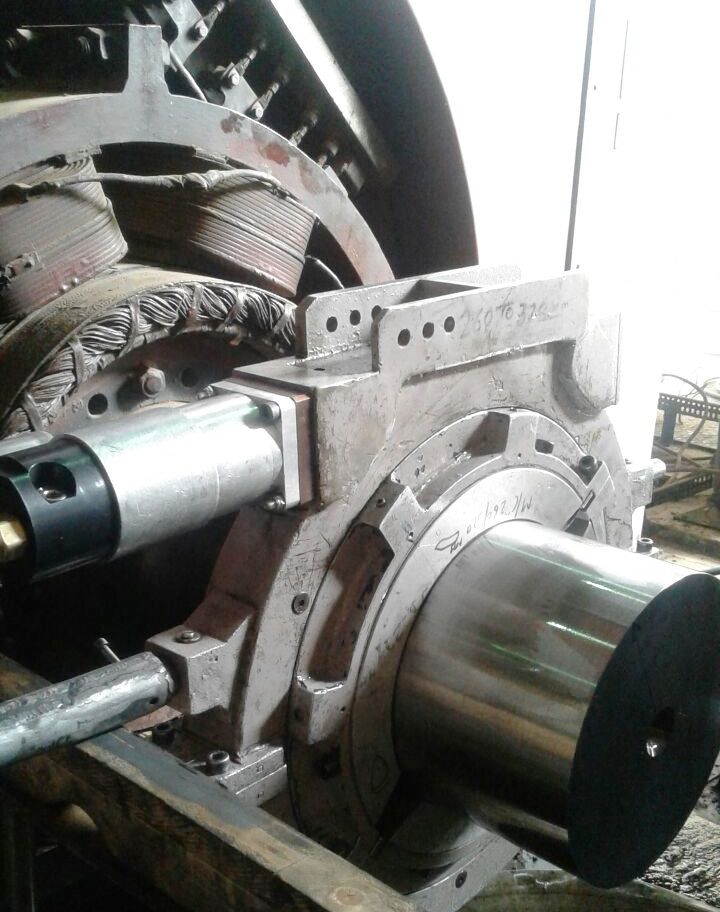

Rotor Shaft Grinding

In case of failure of the white metal rotor shaft bearing it is necessary to inspect the rotor shaft bearing sitting diameter. We undertake complete inspection of rotor shaft, grinding and polishing onsite. The rotor shaft repair, grinding, and polishing are done without dismantling the rotor shaft from the casing. The rotor shaft grinding and polishing is done onsite.

Rotor shaft white metal Babbitt bearings are manufactured and rebabbitting of old rotor shaft bearings is also undertaken. We stand guarantee for the satisfactory performance of white metal babbitt bearings.

Connecting Rod Repair

Connecting rod repair is undertaken with a guarantee, absolutely no need of replacing the connecting rod as in most cases connecting rods can be repaired and re-used.

RA Power Solutions Pvt. Ltd. undertakes in-house repair of connecting rods including re-boring of the big ends and small end, checking of hardness, cracks, etc.

Connecting rods for all make and model of diesel engines like MAN-B&W, Sulzer, Wartsila, Mak, Deutz, Pielstick, Mitsubishi, Daihatsu, Yanmar, Bergen, Niigata, Himsen, Allen, Stork, Fiat, MWM, Hanshin, Caterpillar, SKL, Ruston, Paxman, Crepelle, Mirrlees, Alco, ABC, Nohab, etc.

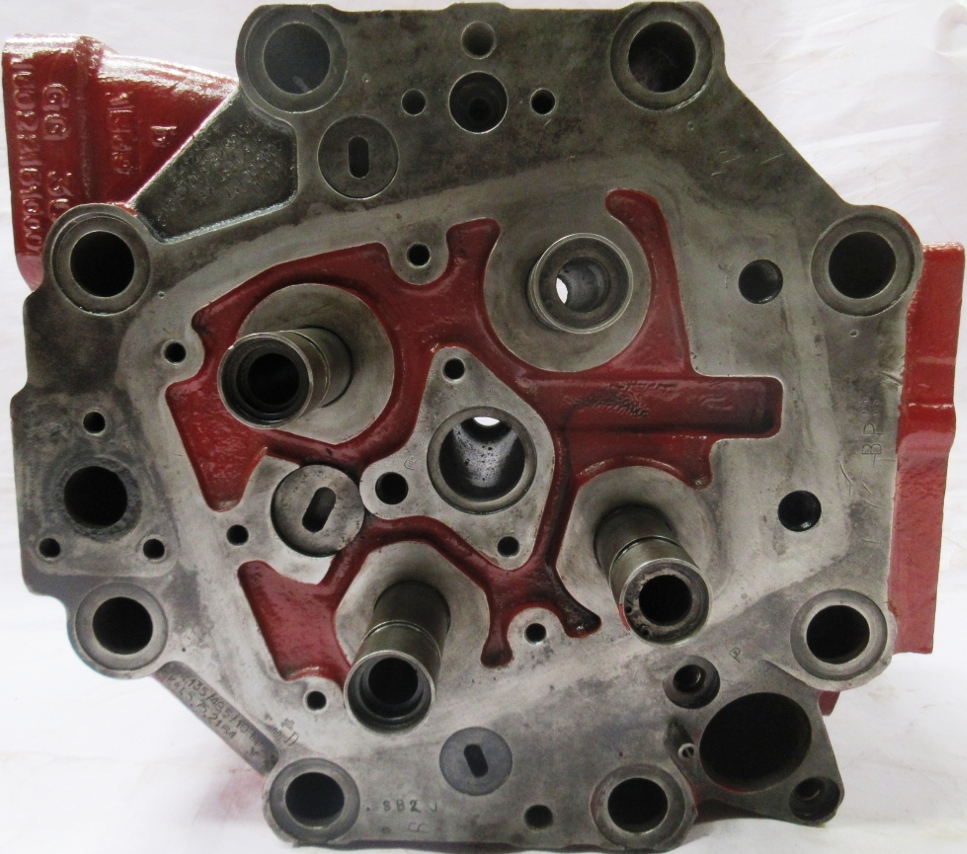

Cylinder Heads

Cylinder Heads are reconditioned at our works. We replace valve seats, valve guides and recondition the cylinder heads which are ready for installation. Repair of cylinder heads is undertaken by our experienced technicians in-house.

The repair of cracks on cylinder heads is done by metal stitching and a metal locking process, which is a cold and proven method of crack repair. Second-hand reconditioned cylinder heads are also supplied with a guarantee at a competitive price.

Rebabbitting of Bearings

Rebabbitting of old white metal bearings of diesel engines, turbines, alternators, and all applications are undertaken. Rebabbitting of white metal bearings is done by a centrifugal process, which ensures dense and uniform bonding with the base steel.

We undertake rebabbitting of bearings up to 1500 mm in diameter. The white metal used for rebabbitting is imported from Spain. The metallurgical certificate for white metal and dimensional inspection report is submitted after rebabbitting of white metal is done. For more information on onsite crankshaft repair services, cylinder liners exporter, cylinder liners, engine cylinder liner, cylinder sleeve manufacturer, metal locking, repair of rotor shaft, and onsite repair services of crankshaft contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.