Your complete compressor crankshaft repair solution :

Are you facing any problem with the crankshaft of your compressor? RA Power Solutions has made the repair of compressor crankshaft easy.

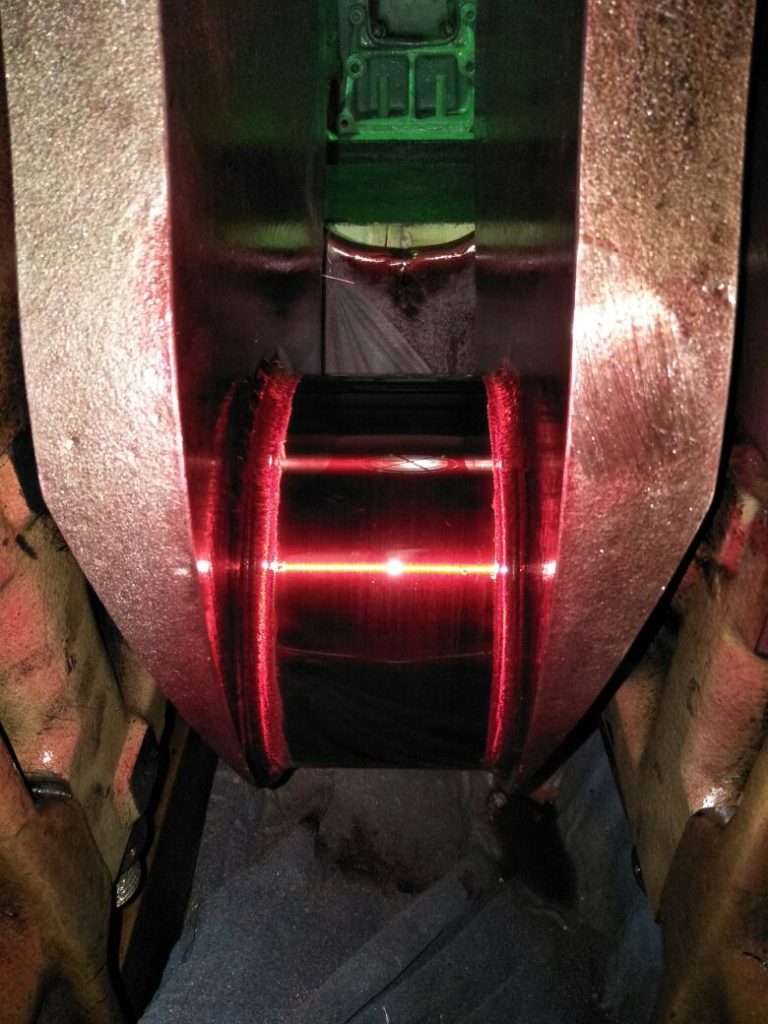

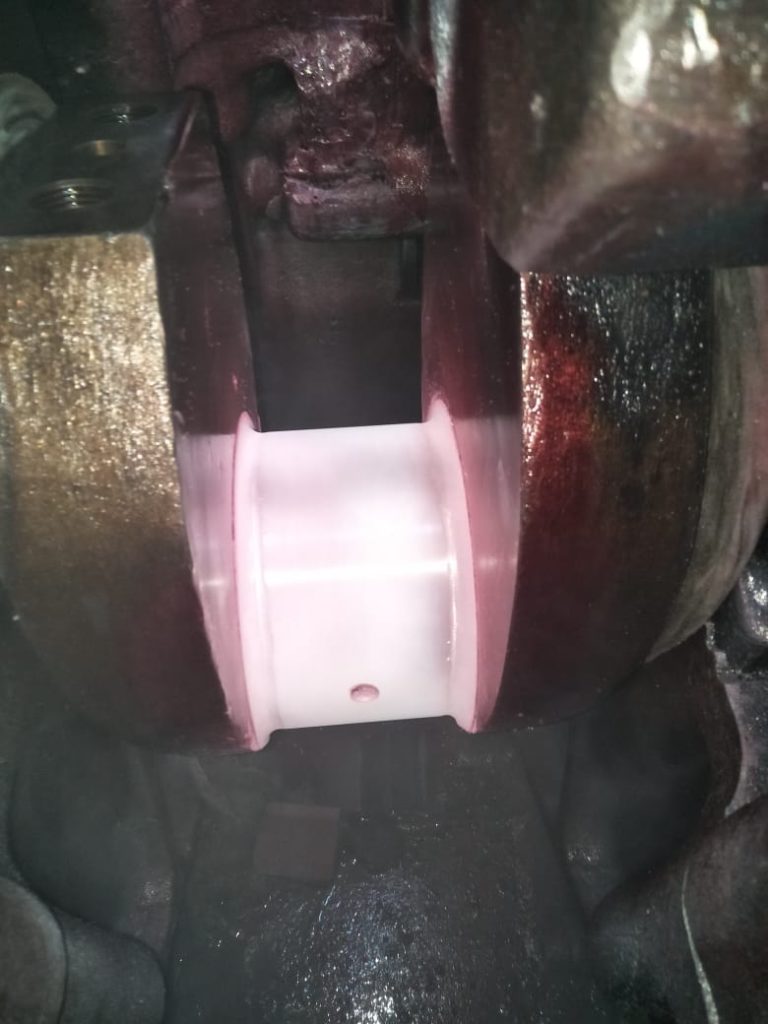

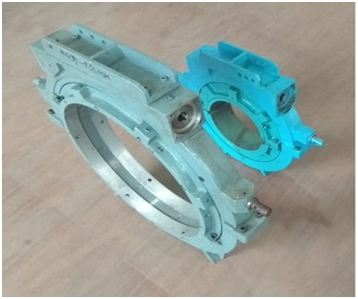

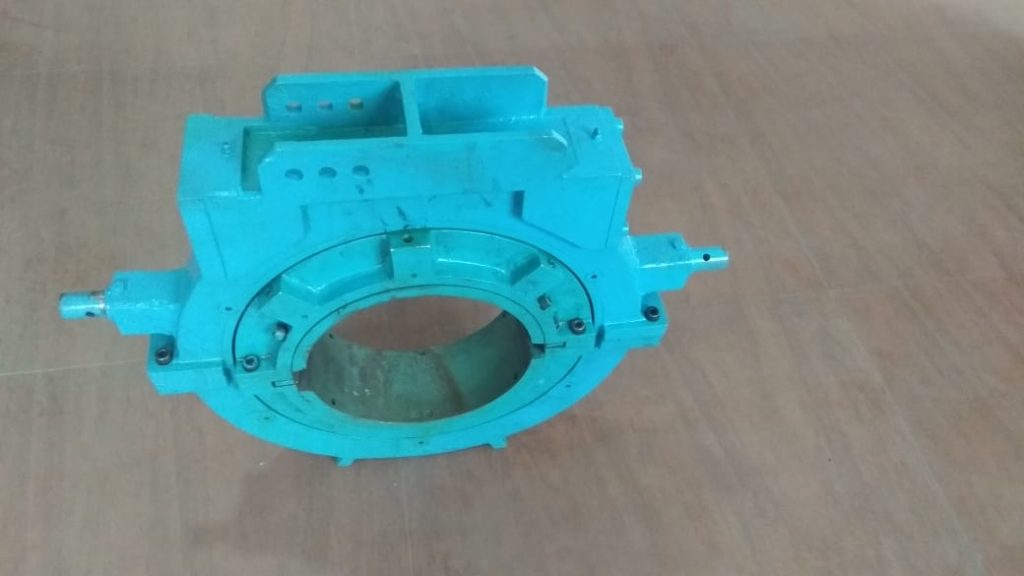

By the introduction of new, revolutionary technology, the compressor crankshaft can be inspected on-site and repaired if required.

Following are the common problems observed in compressor crankshafts :

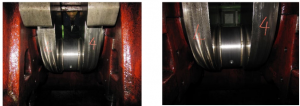

- Excessive wear and tear of crank pin and main journal.

- Increase of oil gap between the crank pin, main journal, and bearing.

- Frequent damage of crank pin and main journal bearings due to development of excessive taper and ovality.

- Seizure of crank pin and main journal bearings on compressor crankshaft due to non-replacement of bearings within the specified time schedule.

- Development of rough surface of crankpin and main journal due to bad quality of lubricating oil and lubricating oil filters.

- Damage of both sides of radius fillet due to an accident.

- Damage of crank pin of compressor crankshaft due to excessive ovality in connecting rod big end bore.

With the introduction of latest technology, there is no requirement of dismantling the crankshaft from compressor casing.

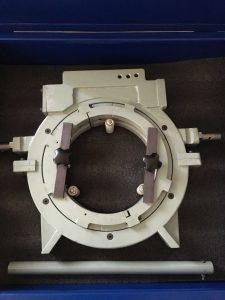

Our technicians visit the site and undertake onsite compressor crankshaft inspection. We have on-site compressor crankshaft polishing and grinding equipment available which is carried by our technicians and repairs are undertaken in no time.

SAVE YOUR COMPRESSOR CRANKSHAFT AND INCREASE THE LIFE:-

We strongly suggest for medium and high-capacity compressors that their crankshafts should be periodically calibrated for taper and ovality, rough surface, hardness, and crack detection.

It is always advisable to get the crankshaft compressor inspected so that corrective action can be taken on time.

The loss of crankshaft brings the whole plant to the stand-still and now can be avoided by availing the expert services of RA Power Solutions, we regularly undertake inspection and repair of compressor crankshaft of Ariel, Cummins, Kirloskar, Samson, Porter-Cable, Stanley Bostitch, Campbell Hausfeld, DeWalt, Makita, Senco, ANEST IWATA, Gardner Denver, Graham Sulzer, Hitachi, Rolair Systems, Brehob, Lufkin, Zebra, Ingersoll Rand, etc.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions India Pvt. Ltd.).

Mr. Shahani is a highly experienced business leader with rich experience of more than 40 years in the field of Power, Heavy, and Shipping industry. He is Technical Adviser to many shipping and heavy industries across the globe.

Mr. Shahani is one of the most enthusiastic professional, and he has all the brilliance of an exemplary leader. Mr. Shahani is an extremely effective coach and mentor of teams and is adept at providing leadership in a global, cross-cultural environment.

For more information regarding crankshaft repair, crankshaft grinders, polishing crankshaft journals, refrigeration compressor crankshaft repair, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.