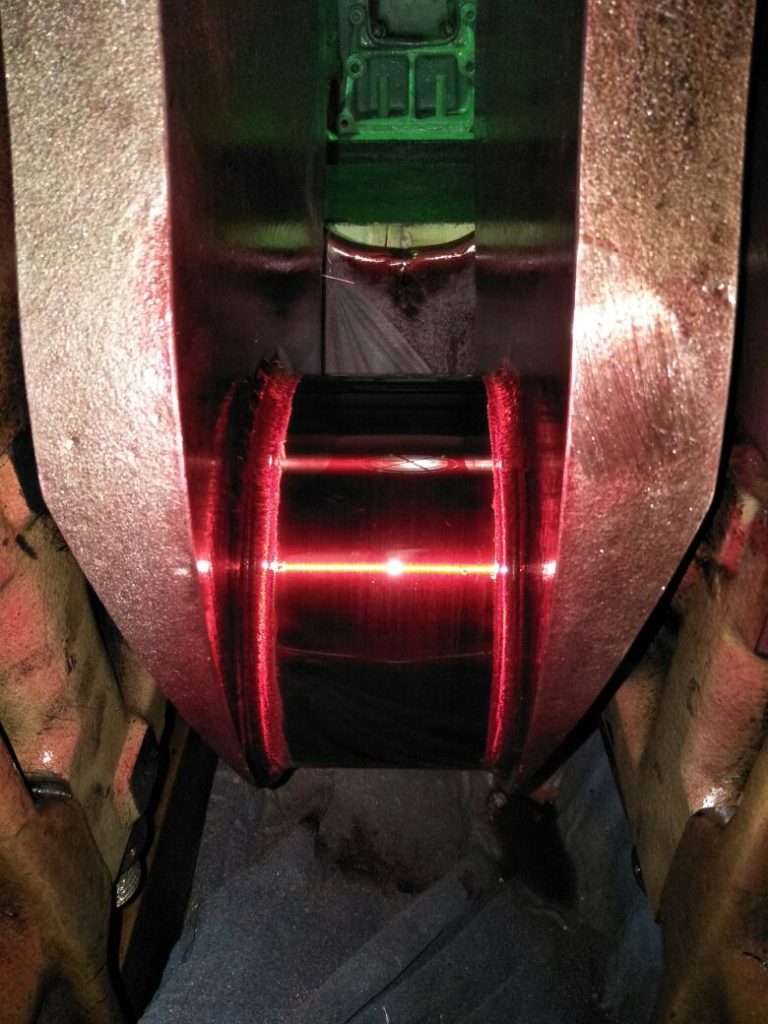

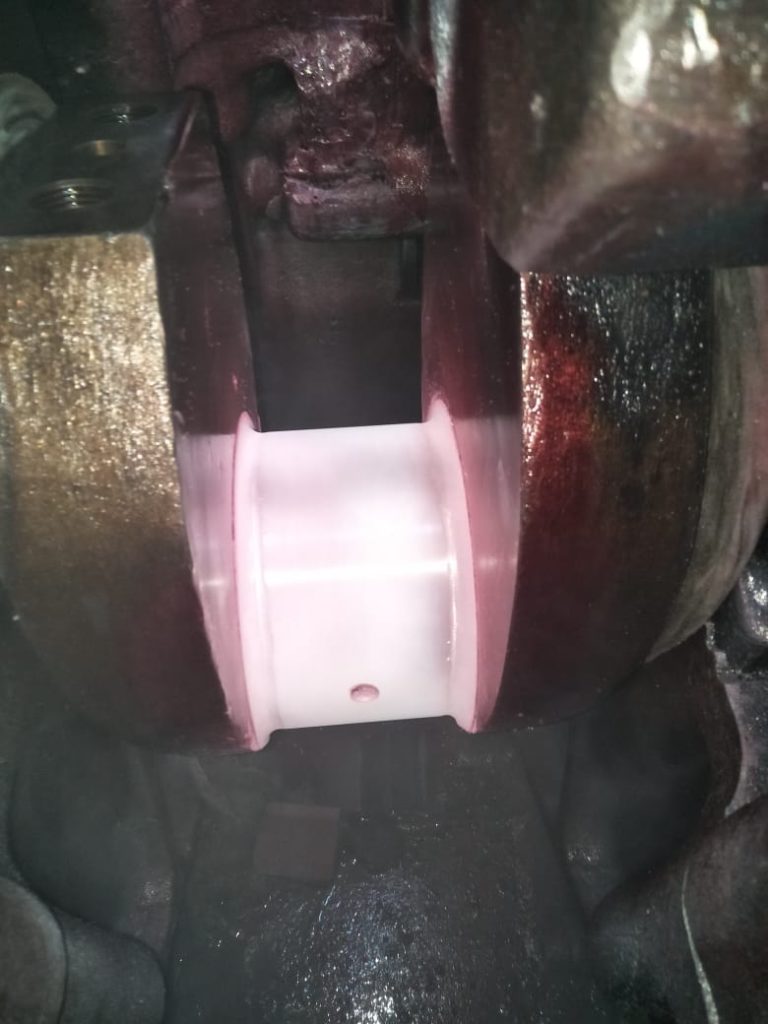

RA Power Solutions undertakes the repair of crankshafts having a diameter ranging from 35 mm to 700 mm. The concept of removing the crankshaft and sending it to the workshop for repair is now no longer valid, and the user gets the crankshaft repaired onsite.

During our working of more than forty years on marine main, crankshaft reconditioning, auxiliary engines, and high capacity diesel generating sets installed in industry, power plants, etc., we have observed that while the maintenance schedule stipulated by the engine manufacturer in the maintenance manual is religiously followed, but no attention is paid on the crankshaft’s condition.

Even during the maintenance schedule of 25,000 to 30,000 hours of operation, maintenance agencies and officials connected with the day-to-day upkeep of the engine ignore the inspection of the crankshaft till the seizure of the bearing or any other major breakdown happens in the crankshaft.

We have experienced that irrespective of the metallurgy of the crankshaft and level of hardness after continuous operation of the engine, taper and ovality of the crankshaft, crankpin, and main journal are developed. The bearing surface becomes rough, and in some cases, bearing line marks, pitting, etc., are developed. Due to these abnormalities developed in the crankshaft, failure of the bearing and the crankshaft takes place. RA Power Solutions recommends that inspection procedures be followed to ensure satisfactory performance of the crankshaft and to save it from rejection.

- During the periodic maintenance schedule, the crankpins and main journals of the crankshaft should be checked for the development of taper and ovality.

- The dimensions of the crankpin, taper, and ovality should be well within the limits specified by the manufacturers. There should not be any presence of bearing line marks or pitting on the crankpin journals.

- The profile of the lubricating oil hole and radius fillet should be checked visually. There should not be any loss of the original profile.

- The hardness test and the crack detection test by MPI or dye penetrant are not required till the major failure of the bearing or accident takes place.

- Checking of deflection of the crankshaft.

- Positioning of crankshaft balancing weights. They should be tightened to a specific torque as per the manual.

In case the above preventive inspection is undertaken on-site without disassembly of the crankshaft, the user can avoid any major damage to the crankshaft.

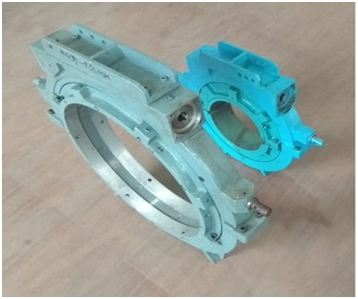

On-site machining of crankpins and main journals has been made simple in this era of technological renovation. The concept of removing the crankshaft and getting the crankshaft machined in the workshop is no longer valid. The onsite crankshaft machining is undertaken to maintain strictly all the tolerances as specified by the manufacturer and stipulated in the maintenance manual.

Crankshaft machining is no longer the monopoly of a bunch of companies based in Europe and the UK. The availability of a portable, easy-to-operate crankshaft grinding machine has made it simple and easy to undertake the polishing and grinding of the main journal if required.

RA Power Solutions is a reputable and leading crankshaft grinding machine exporter and crankshaft reconditioner, known for its high-quality products and exceptional services. With a strong commitment to customer satisfaction, RA Power Solutions has gained a stellar reputation in the industry. Our state-of-the-art crankshaft grinding machines are designed to precision grind and polish crankshafts, ensuring optimal performance and longevity of engines.

RA Power Solutions has been extending onsite crankshaft inspection, main journal grinding, and crankshaft repair services for the last 45 years, We have a team of trained and experienced technicians who can fly to your site on short notice, as all of them have valid CDC.

This blog was written by Mr. Raj Shahani (Managing Director of RA Power Solutions), having more than forty years of experience in providing services like crankshaft repair and grinding, crankpin machining, polishing, and grinding of crankshaft, engine repair, and overhauling, and many other services related to the high-capacity engine.

For any queries regarding crankshaft grinding, grinding of crankshaft, crankshaft grinding services, crankshaft grinding machine, onsite crankshaft grinding, insitu crankshaft grinding repair, crankshaft grinding and repair, Crankshaft Grinding Machine Exporter, onsite crankshaft grinding machine, grinding of main journals, polishing crankshaft journals and crankshaft grinders, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.