RA Power Solutions is a global leader in insitu crankshaft grinding and repair services, with a strong presence at Singapore Port. Known as one of the busiest maritime hubs in the world, Singapore demands fast, reliable, and professional marine repair solutions. RA Power Solutions provides onsite crankshaft grinding in Singapore, ensuring minimal downtime and maximum efficiency for vessels and industries operating in this vital region.

Why Engines Need In Situ Crankshaft Grinding?

Over time, crankshafts face wear and tear due to:

- Continuous operation under heavy loads

- Not enough lubrication or the oil film breaking

- Accidental overloads or sudden stoppages

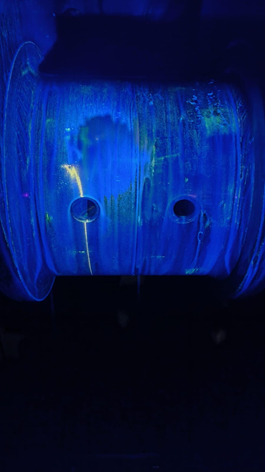

- Metal fatigue and surface damage

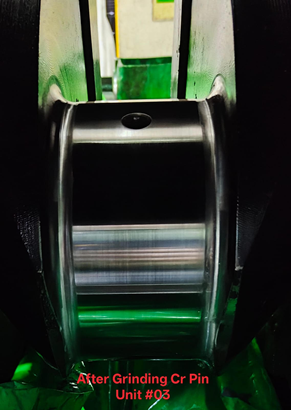

If you don’t repair these problems, they will cause the engine to fail. In situ crankshaft grinding restores the shape, gets rid of ovality, and polishes the surface to OEM tolerances.

Advantages of In Situ Crankshaft Grinding

| Feature | Benefits |

| Onsite Grinding | No engine dismantling or crankshaft removal—faster repairs |

| High-Quality Outcomes | Compliance with or beyond OEM accuracy (taper, ovality, surface finish) |

| Global Reach | Services available onboard vessels and at land-based facilities |

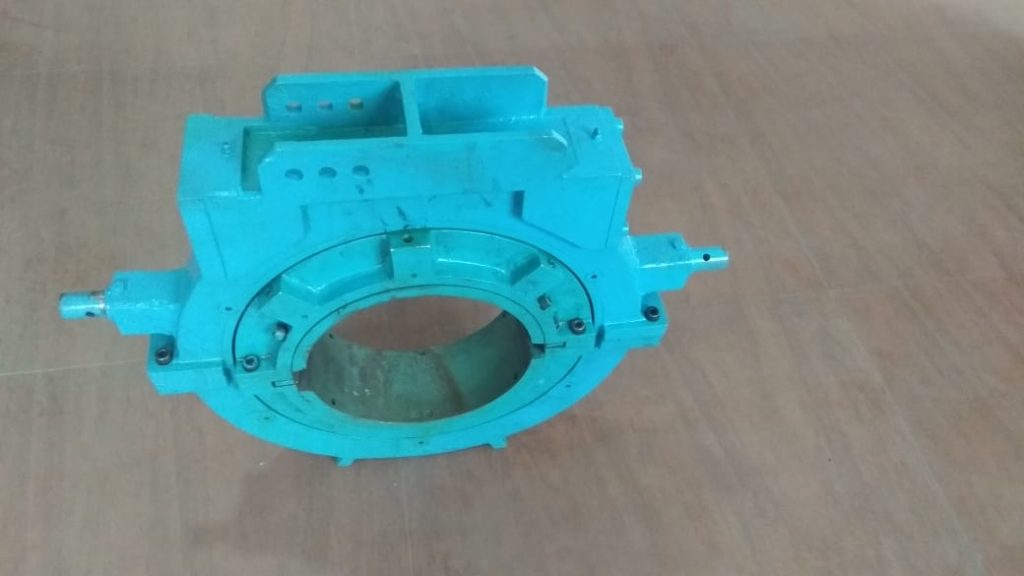

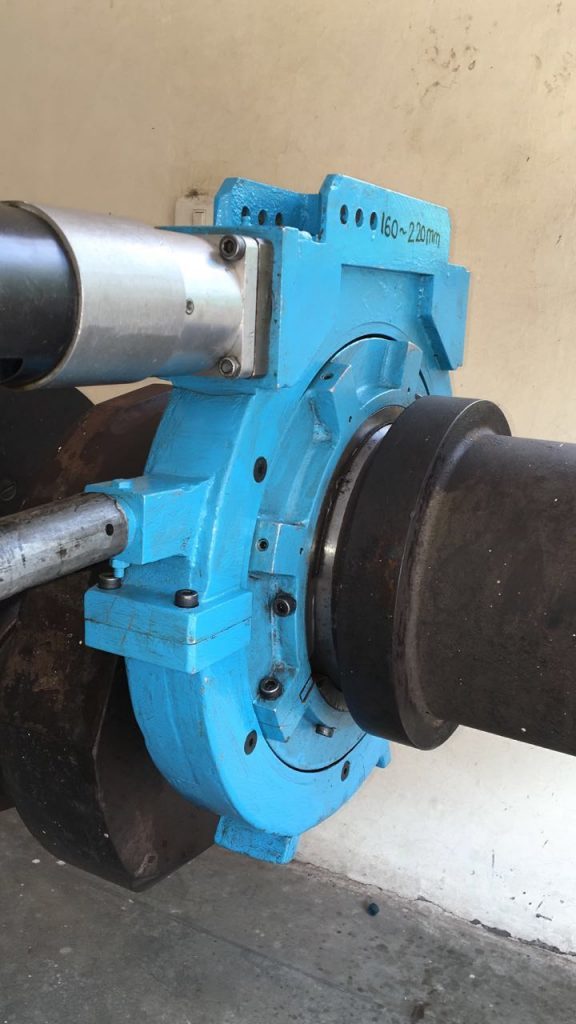

| Portable Grinding Tools | Lightweight and adaptable for deployment in tight or remote settings |

Why RA Power Solutions is the Preferred Choice in Singapore

Onsite Services Across Singapore: We carry out crankshaft grinding and repair jobs directly onboard vessels and at industrial sites anywhere in Singapore.

Portable, Advanced Equipment: Our machines can grind and polish crankpins and main journals of crankshafts ranging from 30 mm to 700 mm in diameter, all within Singapore waters and shipyards.

Serving Singapore’s Maritime Industry: We provide services to leading shipping companies, offshore operators, and industries at Singapore Port.

Proven Track Record: Our engineers have successfully executed hundreds of crankshaft repairs in Singapore, meeting OEM tolerances and international quality standards.

Case Study: Saving a Marine Engine

A shipping company faced an emergency when its main engine crankpin developed cracks mid-voyage. Instead of costly engine removal, RA Power Solutions sent an in situ grinding team onboard. Within 48 hours, the crankpin was ground undersize, fitted with new bearings, and the vessel resumed service. This saved weeks of downtime and thousands of dollars.

Trusted Expertise Backed by Decades

RA Power Solutions offers experienced onsite crankshaft grinding and repair services for all major engine manufacturers, including Caterpillar, Wartsila, Cummins, Yanmar, Daihatsu, MAN, and MAK. Our qualified technicians work in the Middle East (UAE, Saudi Arabia, Qatar, Bahrain, Kuwait, Oman,Singapore, Iran, and Iraq) and the Caribbean, including Trinidad and Tobago, Jamaica, Barbados, and Central America etc.

For more information regarding crankshaft grinding services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.

FAQs:

In situ crankshaft grinding repairs crankpins and main journals directly on the engine block without dismantling.

Engines need this service to fix wear, ovality, surface cracks, and fatigue caused by heavy loads or poor lubrication.

They grind crankshafts with diameters ranging from 35 mm to 700 mm.

It eliminates crankshaft removal and transportation, reducing downtime and repair expenses.

They serve marine, power generation, fertilizer, and heavy engineering industries worldwide, including the Middle East and the Caribbean.