Repair of Crankshaft is undertaken by RA Power Solutions Pvt. Ltd. The most common defects in crankshaft are as following:

- Development of taper and ovality beyond the stipulated manufacturer’s tolerance

- Development of cracks due to seizure of bearings or damage to crankshaft crank pin and main journal diametre.

- Deep bearing line marks and rough surface of crankpin and main journal

- Loss of alignment of crankshaft.

- Damage of counter weights, key way for mounting of driving gear.

|

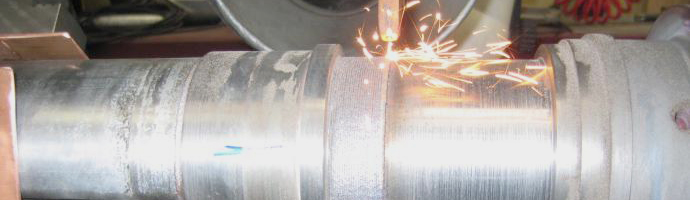

Repair of Crankshaft is in Process |

Crankshaft on V Block |

|

|

|

RA Power Solutions Pvt. Ltd. has more than 37 years of experience of successfully executing repair of crankshaft irrespective of type of damage it has. The grinding of crankshaft in most of the cases is done onsite.

We have state of the art crankshaft grinding equipment which is portable and lightweight and can be carried to the site. More than 11000 jobs for crankshaft grinding and repair up to 700 mm diameter have been executed.

RA Power Solutions Pvt. Ltd. also sells onsite crankshaft grinding machine for grinding of crankshaft which is easy to operate.

We provide free training to the technicians for repair and grinding of crankshaft.

|

MPI of Crankpin for Crack Detection is in Process |

Crankshaft Grinding is in Process |

| |

|

|

Crankshaft Grinding Machine Under Grinding Process |

Crankshaft Grinding Machine from Inspection Window |

| |

|

|

Before and After Grinding of CR Pin |

Crankpin After Repair |

| |

|

Contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383 for more information.