In fields including maritime, power generation, oil and gas, and heavy industry, where engine performance affects productivity, a crankshaft failure might stop work completely. When that happens, time equals money, and typical repair procedures are no longer efficient.

This is when in situ crankshaft grinding is the better option.

We at R A Power Solutions are experts in In Situ Crankshaft Repair and Insitu Crankshaft Machining. We can do it quickly, reliably, and to OEM standards, no matter where you are in the world.

What is meant by “in situ” crankshaft grinding?

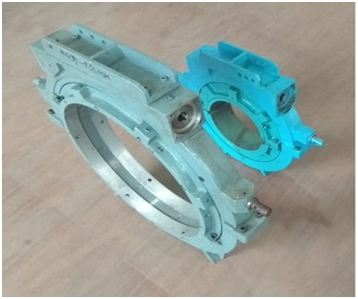

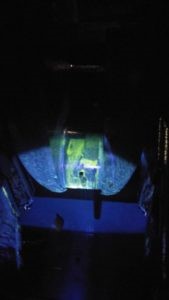

In Situ Crankshaft Grinding is a new method that lets you grind and polish broken crankpins and main journals right where they are, without taking the crankshaft out of the engine casing. This cuts down on the time, money, and hassle of taking apart and moving heavy parts.

Why Should You Choose In Situ Crankshaft Repair?

Crankshafts can be damaged by bearings that fail, overheating, being out of alignment, and not having enough lubricating oil. If these problems aren’t fixed right away, they can cause the engine to fail completely.

Insitu crankshaft repair can fix these problems before they get worse. At R A Power Solutions, we offer the following services:

- Machining the crankshaft in place to fix the surface shape

- Grinding crankpins in place to exact OEM specifications

- In-place crankshaft grinding repair for scoring, ovality, and taper

- Polishing and reconditioning on site to make the crankshaft last longer

The main services we offer

R A Power Solutions offers a full range of in situ crankshaft grinding services that are built to be accurate and dependable:

1. Machining the crankshaft in situ

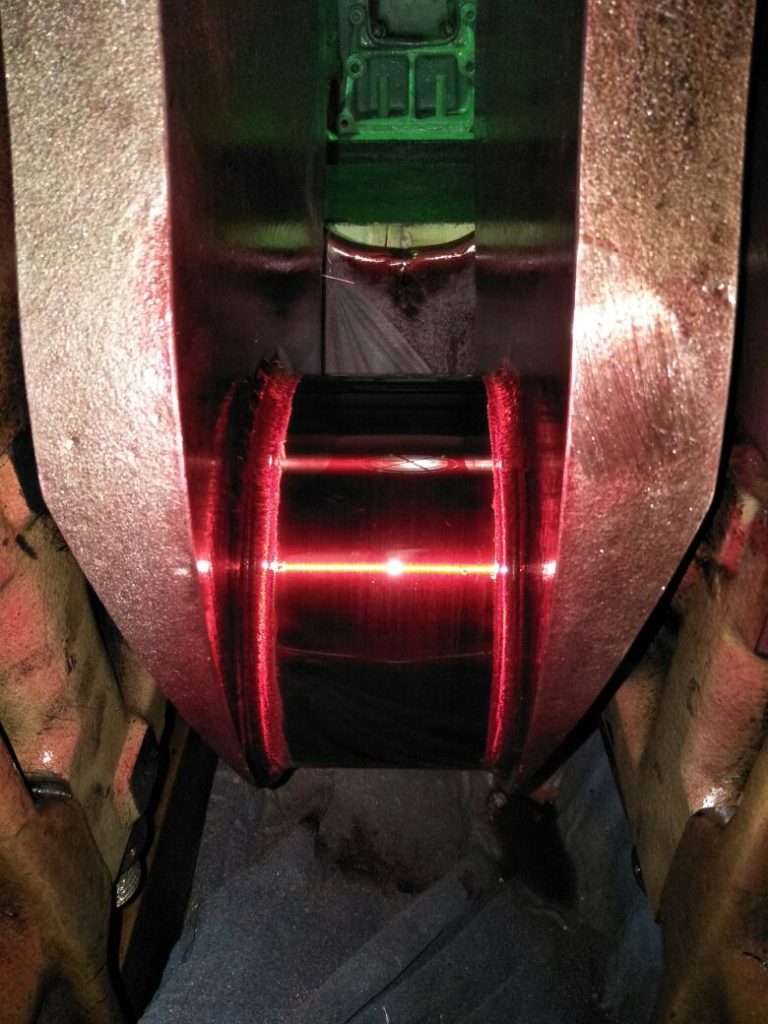

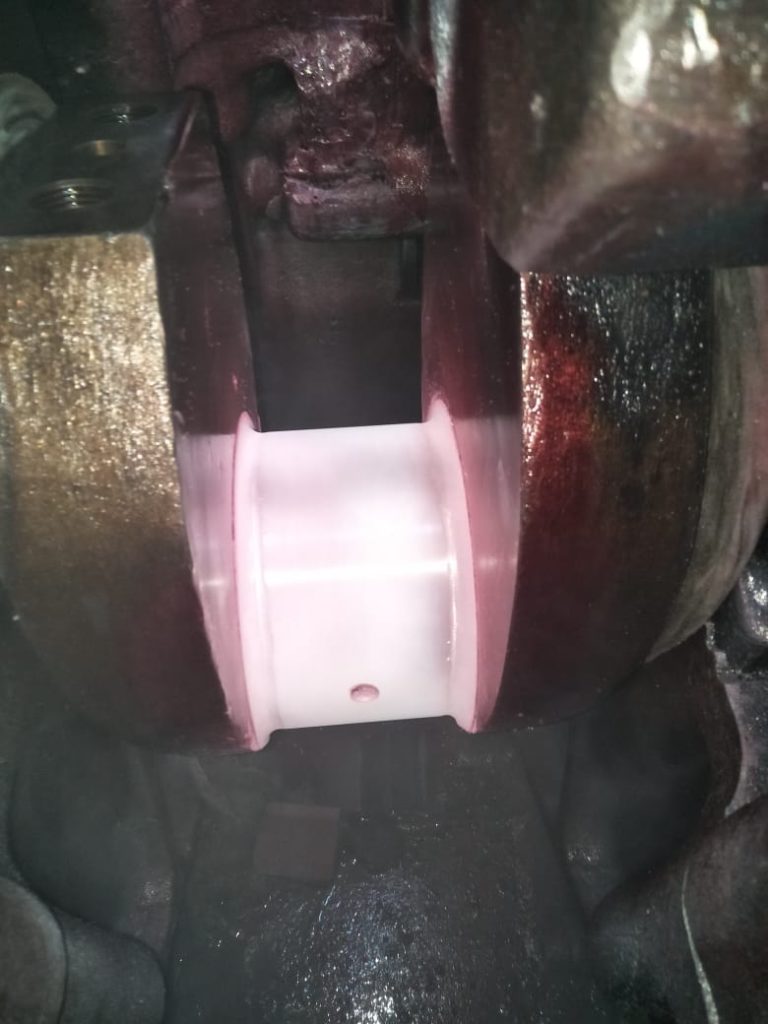

We use portable CNC machining units to fix broken crankpin and main journal diameters, making sure they are perfectly round and have a smooth surface.

2. Services for repairing crankshafts in place

Our professionals offer custom crankshaft solutions on ships, offshore rigs, power plants, and distant industrial sites, from small scratches to big wear.

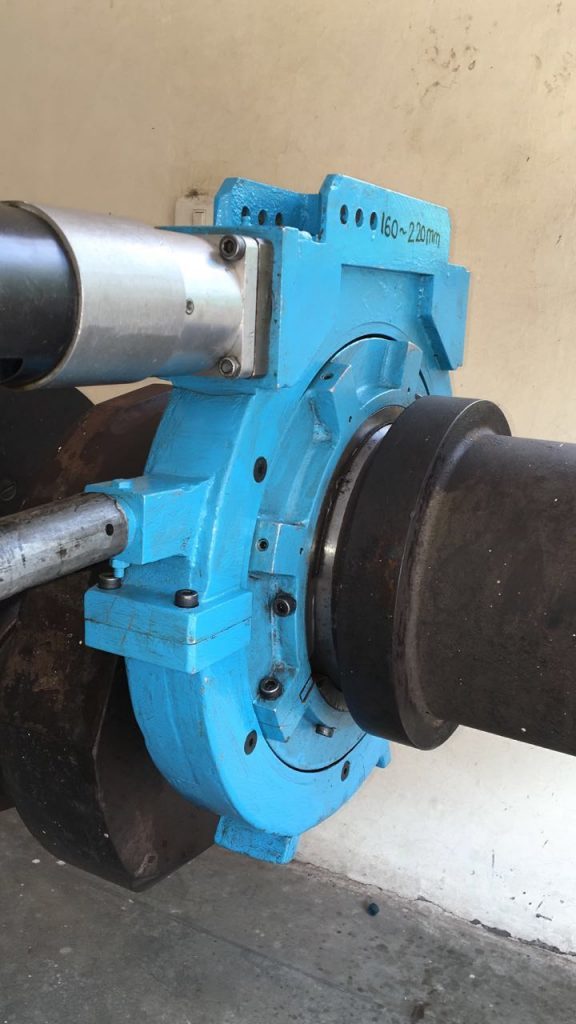

3. In Situ Grinding Machine for Crankshafts

Our unique grinding machines are small, very precise, and can handle crankshafts of any size, from 30 mm to 700 mm. They are made to work without vibration, so they can grind accurately even in the tightest spaces.

4. Machining and polishing of crankshaft in place

We grind and polish at the same time to get the best surface finish, lower friction, and make bearings more reliable and the engine work better overall.

The Main Benefits of Our In Situ Services no need to take apart or move it

- Tolerances and surface finishes that meet OEM standards

- A lot of time and money saved

- Open 24 hours a day, seven days a week in more than 90 countries

- Technicians with more than 45 years of experience working around the world

- Full inspection and final report paperwork

Industries We Work With

People trust our onsite crankshaft machining and repair services:

- Marine transportation firms (repairs for main engines and auxiliary engines)

- Power plants (fixing crankshafts on diesel and gas engines)

- Oil and gas industries (FPSOs and offshore rigs)

- Operators of mining and heavy equipment

We bring the answer to your site, no matter how far away or complicated your operation is.

A History of Success Around the World

Our staff has done thousands of successful repairs all over the world, from fixing things on container ships in Europe to machining and fixing crankshafts in power stations in Africa. Each job is done with an unsurpassed level of accuracy and a promise to make the engine last longer while keeping downtime to a minimum.

Work with the best in the business at crankshaft grinding. RA Power Solutions is a world leader in in situ crankshaft grinding repair. They have a long history of expertise and innovation. Because we care about quality, speed, and customer satisfaction, ship owners, plant managers, and engine manufacturers all around the world choose us as their partner.

Get in touch with us today.

Our team of professionals can fix your crankshaft so that it works at its best, no matter where you are or when you need it.

- Call: +91 9582647131

- Email: rajshahani@rapowersolutions.com

- Website: www.rapowersolutions.com

If your crankshaft breaks, you don’t have to wait a long time or pay a lot of money to fix it. R A Power Solutions offers world-class In Situ Crankshaft Grinding Services that are fast, accurate, and can be done anywhere.

If you need to machine and polish a crankshaft on site, trust the company that sets the standard for the whole world.

R A Power Solutions: Built to Work. Made to Last.

FAQs

It’s the onsite grinding of crankshaft journals without removing the crankshaft from the engine.

When crankpins or journals have wear, scoring, taper, or ovality.

From 30 mm to 700 mm in diameter.

It saves time, avoids engine dismantling, and reduces costs.

Marine, power plants, oil & gas, mining, and heavy industries.