Crankpin grinding and crankpin repair by an in situ crankshaft grinding machine are offered by RA Power Solutions through a highly motivated team of technicians with over four decades of experience in crankshaft grinding and crankshaft repair. The crankshaft must be initially inspected by experienced technicians to detect any faults. That may have occurred after damage or an accident.

The following are the major parameters that are examined before the repair of the crankshaft:

- The minimum and maximum diameters of the crankpin and main journal, taper, and ovality are checked.

- Run out of the main journal, and deflection readings are taken to verify the loss of alignment.

- A complete non-destructive test using MPI and an ultraviolet lamp for heat cracks is undertaken of the crankpins and the main journal of the crankshaft.

- The crankshaft is also subject to a hardness test.

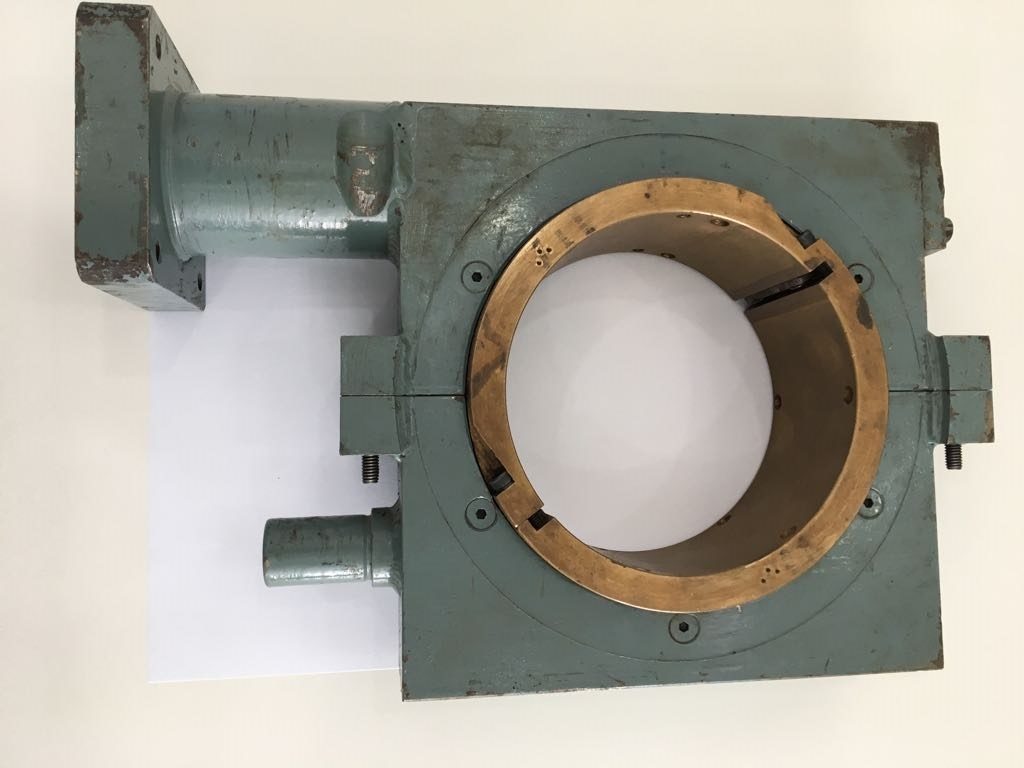

Based on the preliminary inspection reports prepared by the technicians, the repair procedure is planned. The onsite crankshaft grinding machine used for the crankshaft repair is lightweight. It is placed on the damaged crankshaft from the inspection window of the engine block. There is no requirement to remove the crankshaft from the Entablature and send it to the workshop, as bench-type grinders are now outdated.

The crankshaft grinding and crankshaft polishing are undertaken to maintain taper and ovality, surface finish as per the OEM requirement. RA Power Solutions has facilities to undertake in situ crankshaft grinding, crankshaft polishing, and repair of crankshafts up to a diameter of 700 mm without removing the crankshaft from the engine block.

During and after the repairs, all the major technical parameters are checked, and a calibration report is prepared. It is possible to execute the crankshaft grinding and crankshaft repair on board a vessel while it is sailing. Technicians have seaman passports and can travel to any part of the world in the shortest possible time. Thus, attending to the damaged engine in a short time. We are class-approved and stand to guarantee the satisfactory performance of the crankshaft after repairs.

We are commonly working on the following engines:

Wartsila, Daihatsu, Mirrless Blackstone, Yanmar, Allen, MAK, MAN, B&W, Sulzer, Caterpillar, Fiat, Mitsubishi, MTU, Cummins, Deutz, Nohab Polar, Wartsila 12V32, Wartsila 18V32, Pielstick, Bergen, Detroit Diesel, MAK 552, MAK 453, MAK 451 AK, Niigata, MAK 452 AK, Ruston, Lister Blackstone K8 Major MK2, Volvo Penta, etc.

For more information on insitu crankshaft grinding repair, insitu crankshaft repair and grinding, onsite grinding machine supplier, and repair of crankshaft, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.