RA Power Solutions is based in New Delhi, India, undertaking crankshaft machining for the last 45 years. Crankshafts are repaired on site without removing them from the crankcase. In case of any damage to the crankshaft, crankpin, and leading journal, we can machine it and polish it to a standard undersize within the manufacturer’s specification and tolerances specified.

The main advantage of repairing a damaged crankshaft and crankpin journal onsite is the short repair timescale. It is also more cost-effective. There is no need to remove the crankshaft from the engine block, pack it, or send it to a workshop. Machining and polishing can be done directly on-site. At the same time, all the specifications and tolerances as per the engine manufacturer are maintained.

RA Power Solutions has a team of experienced engineers who can repair all types of defects in the crankshaft and make it reusable.

Our scope of work includes the following:

- Crankshaft, Crankpin Repair

- Crankshaft Journal Repair

- Crankshaft Repair

- Crankshaft Straightening

- Crankshaft Regrinding

- Crankshaft Polishing

- Crankpin Machining, Crankshaft Journal Machining

We can undertake the repair and polishing of crankshafts with diameters ranging from 35 mm to 700 mm. Our technicians can fly to any part of the world at short notice. As they carry with them the Indian CDC. The machining of the crankshaft, repair of spare parts, engine overhauling, and maintenance can also be undertaken while sailing the vessel.

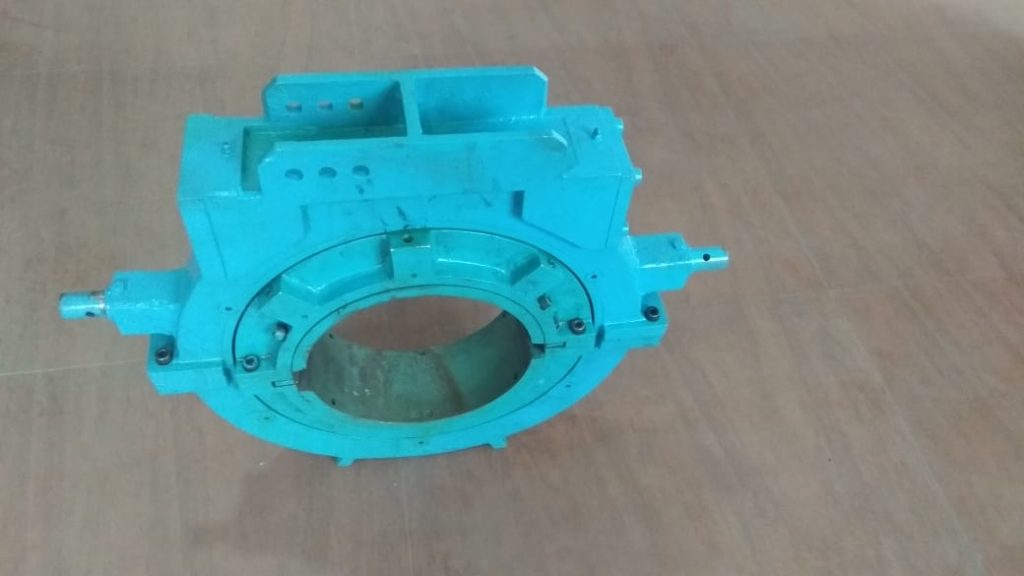

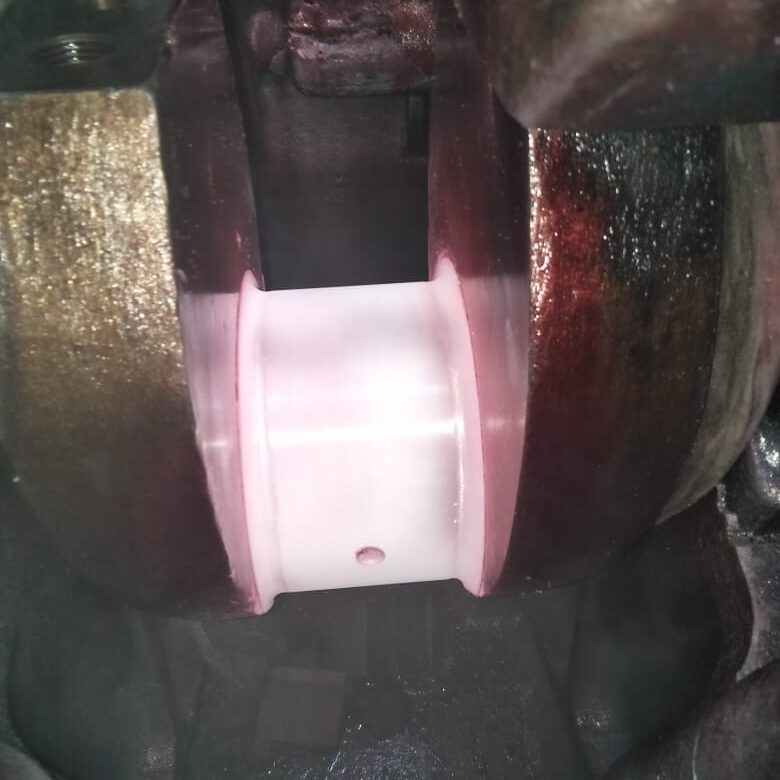

Our portable, lightweight onsite crankshaft grinding machine is designed to generate minimum vibration. Thus, maintaining a high standard of quality in terms of surface finish, taper, and ovality. Since we offer repair of primary spares, maintenance, and overhauling of engines, spares, etc. We own one point of responsibility for the satisfactory performance of the engine in totality.

We are considered to be the cheapest in the market in comparison to the competitors based in Europe.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions), who has more than forty years of experience in the field of crankpin machining, crankshaft journal machining, crankshaft grinders, polishing and grinding of crankshaft, etc. For more details on babbitt bearing, white metal bearing, crankshaft grinding services, engine block repair, main journal grinding, grinding of crankshaft, or crankshaft grinders, email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.