Grinding of the rotor shaft is required due to wear and tear of the rotor shaft diameter, damage to the rotor shaft bearing seating area, or failure of the bearing. RA Power Solutions undertakes onsite grinding and polishing of rotor shafts having diameters up to 700 mm. The initial inspection of the rotor shaft is conducted by experienced technicians, which includes crack detection by MPI, hardness test, and dimensional inspection.

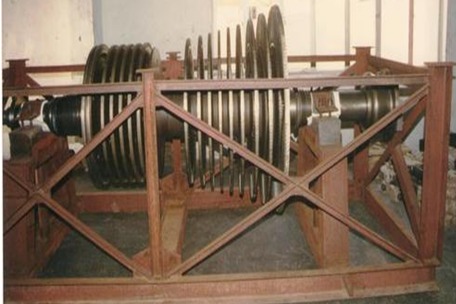

Onsite grinding of the rotor shaft is performed using the latest design of rotor shaft grinding machine. It was developed and manufactured by RA Power Solutions. The rotor shaft grinding machine has almost zero vibration, which helps to maintain the tolerance of the rotor shaft. Their bearing sitting area up to 20 microns.

RA Power Solutions Pvt. Ltd. has successfully executed more than one thousand jobs of grinding rotor shafts, crankshaft grinding, and rotating equipment.

RA Power Solutions specializes in the comprehensive refurbishment of rotor shafts. Our expert team employs cutting-edge techniques to restore your rotor shafts to their optimal condition. Enhance reliability and efficiency while extending the lifespan of your critical components. Trust us for top-notch rotor shaft refurbishment services. For information on the refurbishment of the rotor shaft, grinding of main journals, and Onsite Rotor Shaft Grinding Machine, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.