There is no need for the replacement of major components of the engine or the equipment installed in heavy engineering plants in case of the development of a crack or damage to the casting. It is possible to undertake onsite repair of cracks and damaged components irrespective of their application and profile by metal stitching and the metal locking process.

The main features of undertaking crack repair and repair of damaged casting of engine block and heavy cast components by metal locking are as follows:

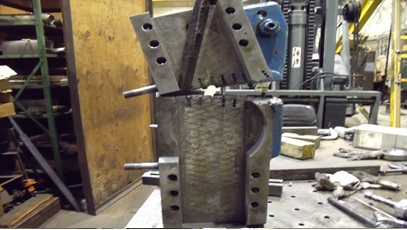

- RA Power Solutions uses the cold process of metal lock. The metal stitching is used for the repair of cracks and damaged components.

- It is possible to replace a large portion of damaged components. By using a new casting piece, which is done by metal stitching and a metal locking process.

- Metal stitching and metal locking are the most trusted technologies of crack repair, as no heat is generated. It is a cold process, and there is no change in the shape and profile of the component, unlike in the welding process.

- Repair of the crack by metal stitching and metal locking is possible onsite without disassembly of the equipment.

- The crack repair and the repair of the damaged casting by the lock. The stitch method is far more cost-effective than the purchase of expensive new parts.

The only company providing crack repair services on board the vessel while it is sailing. All repairs undertaken are guaranteed by RA Power Solutions engineers. A company with four decades of experience.

To know more about metal stitching, engine cylinder liner, metal stitching engine block, cold stitching cast iron, cold stitching engine blocks, metal surgery, and cast iron crack repair, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383 for more information.