Crankshaft Grinding or crankshaft repair is required in case of the development of taper and ovality in the crankpin or crank main journal.

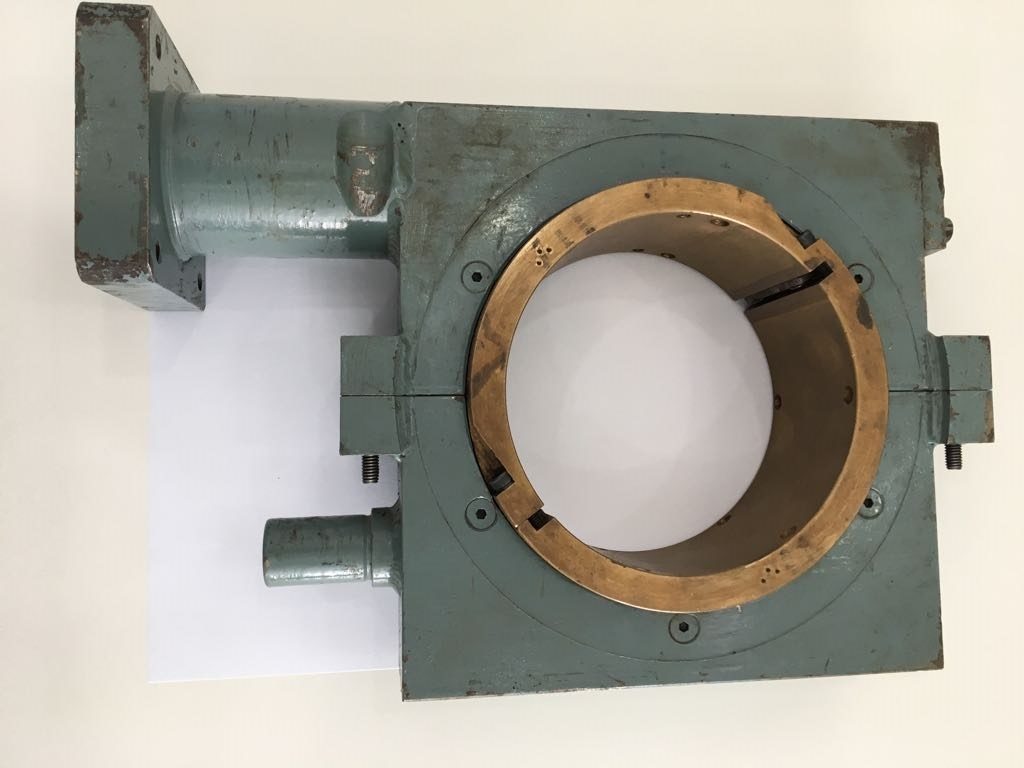

In case of an accident or bearing failure, the crankshaft needs grinding and repair. RA Power Solutions, having experience of more than 4 decades in the repair of crankshafts of high-capacity marine engines and diesel engines installed in power plants has introduced an onsite crankshaft grinding machine that is capable of undertaking machining, grinding, and polishing of crankshaft, main journal, and crankpin onsite without disassembly of the engine. It is easy to operate and can be taken to the site.

RA Power Solutions, as a repair company, has been using the Crankshaft Grinding machine for more than 45 years and has executed more than 20,000 jobs of repair and grinding of crankshafts. The performance of the machine is proven and is highly recommended by the leading workshops undertaking the repair and grinding of crankshafts in various countries like Sudan, Nigeria, Singapore, Dubai, South America, Indonesia, Mauritius, Greece, Singapore, Dubai etc.

The machine is available at a low cost, and job training is provided.

For more information on Dubai marine engine crankshaft grinding services, grinding of crankshaft, or crankshaft grinder machine, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.