RA Power Solutions has now made it easy to undertake crankpin grinding, crankpin repair, and crankpin polishing onsite in a short time with the lowest cost.

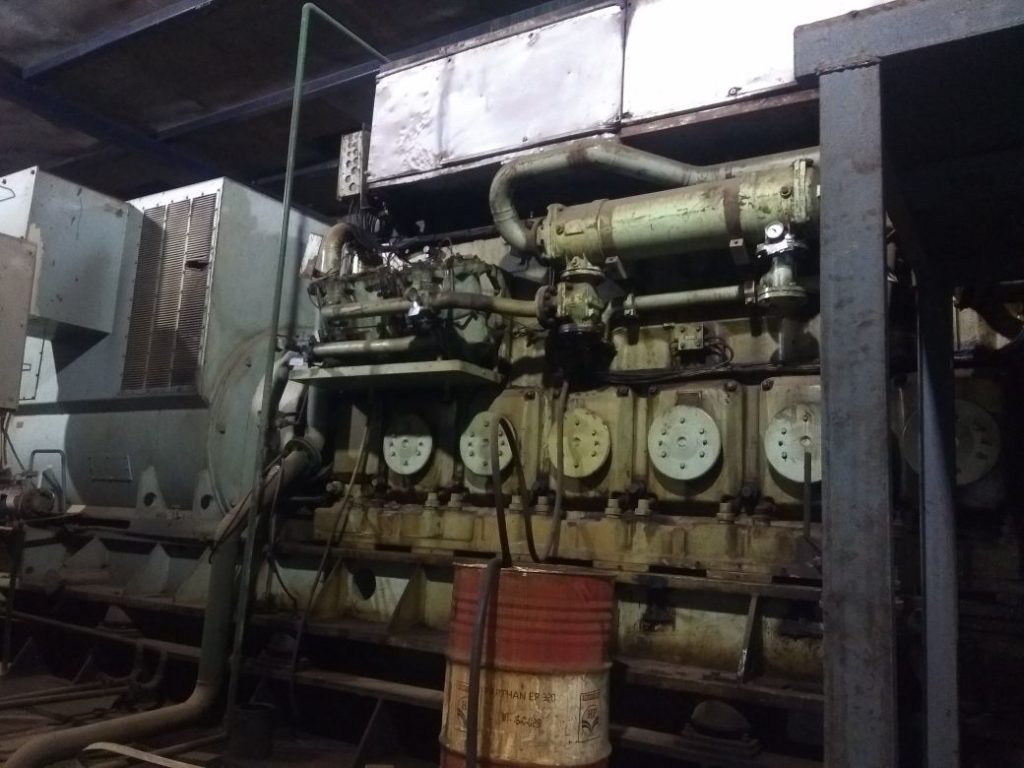

We undertake onsite crankpin repair, crankpin grinding, and crankpin polishing of crankshaft diameters ranging from 30 mm to 700 mm. This is undertaken by a lightweight, easy-to-operate, and portable onsite crankshaft grinding machine, which is taken to the site. We have a team of experienced technicians having valid passports and CDC. They can travel to any destination in the world in the shortest possible time with portable crankshaft grinding equipment and can also undertake repairs while sailing of vessel.

The following procedure is generally followed for successful onsite crank pin repair of the crankshaft:

- Initial dimensional inspection of the crankpin is undertaken by calibrated measuring instruments for taper, ovality, and other parameters.

- The radius fillet, lubricating oil hole of crankpin, is checked for any loss of profile and damage.

- Crack detection test by high-intensity MPI torch is undertaken by level 3 qualified technicians.

- Hardness check and other important parameters are checked and recorded.

After the initial inspection, in case required grinding and polishing of the crankpin is undertaken, to maintain the tolerances strictly as per the manufacturer’s specifications.

The onsite crankshaft grinding machine used by RA Power Solutions engineers for grinding and polishing of crankpin and crankpin repair is self-designed and is improved from time to time.

The combination of skilled technicians and the most modern onsite crankshaft grinding machine is used for crankpin grinding, delivering and maintaining the tolerances after crankpin repair, which is better than the international standards and the tolerances specified by the engine manufacturers. Our company has more than four decades of experience in successful repairs of the crankshaft of high-capacity engines used for power generation, shipping, etc.

RA Power Solutions also provides the following onsite repair services:

- Machining and grinding of crankpin journals up to 700 mm diameter.

- Grinding of main journals

- Machining and grinding of crankpin fillets

- Grinding and Machining of main journal fillets

- Machining and grinding of the intermediate shaft/tail shaft

- Grinding and polishing of crankshaft, turbine shaft, alternator shaft, and pump shaft

- Metal stitching/metal locking of the damaged casting

- Overhauling and repair of the engine.

- Rebabbitting of old white metal bearings

The author is Mr. Raj Shahani, the company’s managing director. He has 45 years of experience providing on-site repair services related to high-capacity engines worldwide. He designed and developed the portable crankshaft grinding machine to save time and money.

For more information regarding grinding of crankshaft, onsite crank pin repair, onsite repair services, and crankpin repair, please feel free to write us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.