When it comes to marine diesel engines, every component is critical to ensure smooth operation—including crankpin bearings. These frequently overlooked components are required for connecting rods to revolve smoothly around the crankpin, carry huge loads, and withstand intense combustion forces.

What Are Crankpin Bearings?

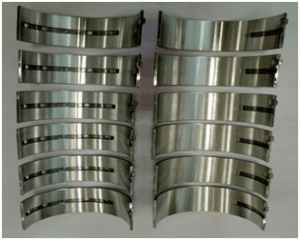

A crankpin bearing, which is also referred to as a rod bearing journal, is a precision component that is located between the crankshaft and connecting rod. Its purpose is to facilitate seamless rotation, minimize friction, and reduce wear. Plain or tri-metal varieties are frequently employed in marine applications due to their high-load capacity and durability.

Why Undersized Crankpin Bearings Matter on Ship Engines?

During engine overhauls or crankshaft grinding, standard-size bearings often no longer fit correctly. This raises a serious issue. Suppliers rarely keep undersized bearings in stock, especially for older engine models that manufacturers have discontinued.

RA Power Solutions: Reliable, Precision Solutions

With over 45 years of global service, RA Power Solutions specializes in:

- Sourcing tri-metal bearings from reputable manufacturers in the UK, Germany, and Japan

- Providing custom undersized crankpin and main journal bearings—even for long-discontinued engine models

- Onsite crankshaft repair services anywhere in the world.

Crankpin Bearings for Different Marine Engines

At RA Power Solutions, we stock and supply standard and undersized crankpin bearings for a wide range of popular marine engines. We design our solutions to fit after crankshaft grinding. They ensure minimal downtime and reliable performance

| Engine Make | Engine Model | Bearing Type | Undersize Availability | Applications |

| Yanmar | S185L | Tri-Metal / Plain | 0.80 to 2.00 mm | Marine propulsion & power plants |

| Daihatsu | 5DC-17 | Tri-Metal | 0.50 to 4.00 mm | Auxiliary engines on ships |

| MAN | L28/32 | Tri-Metal | 0.50 to 2.00 mm | Marine main engines |

| MAK | M32C | Tri-Metal | 0.50 to 2.50 mm | Heavy-duty marine & industrial |

The Role of Crankpin Bearings in Engine Longevity

- Friction Reduction / Hydrodynamic Function: These bearings utilize an oil film to separate metal surfaces, significantly lowering wear and safeguarding the crankshaft.

- Load & Shock Absorption: Especially critical in high-load marine engines, these bearings help dampen combustion forces while maintaining alignment.

- Cost-Effective Maintenance: Designed to be replaceable, they protect expensive components like the crankshaft itself from damage. The alternative—machining new bearing surfaces—would make engine rebuilds far more costly.

For more details of the Crankpin Bearings for Marine Diesel Engines, undersized crankpin bearings, Tri-Metal Bearings, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Crankpin bearings support the connecting rod on the crankshaft, reducing friction and wear.

You need undersized crankpin bearings after crankshaft grinding. Standard bearings no longer fit.

MAK, MAN, Yanmar, and Daihatsu diesel engines commonly use them.

They minimize friction, absorb loads, and protect the crankshaft from damage.

RA Power Solutions supplies standard, undersized, and custom crankpin bearings worldwide.