RA Power Solutions is a pioneering name in the realm of onsite machining services. With a commitment to precision and excellence, they offer a comprehensive suite of solutions aimed at addressing complex machining challenges without the need for equipment dismantling.

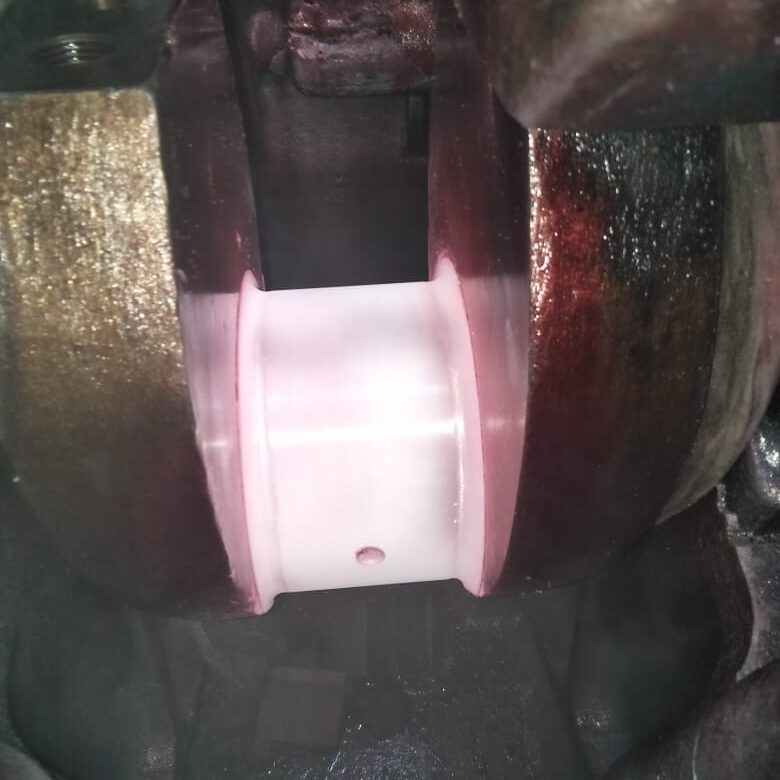

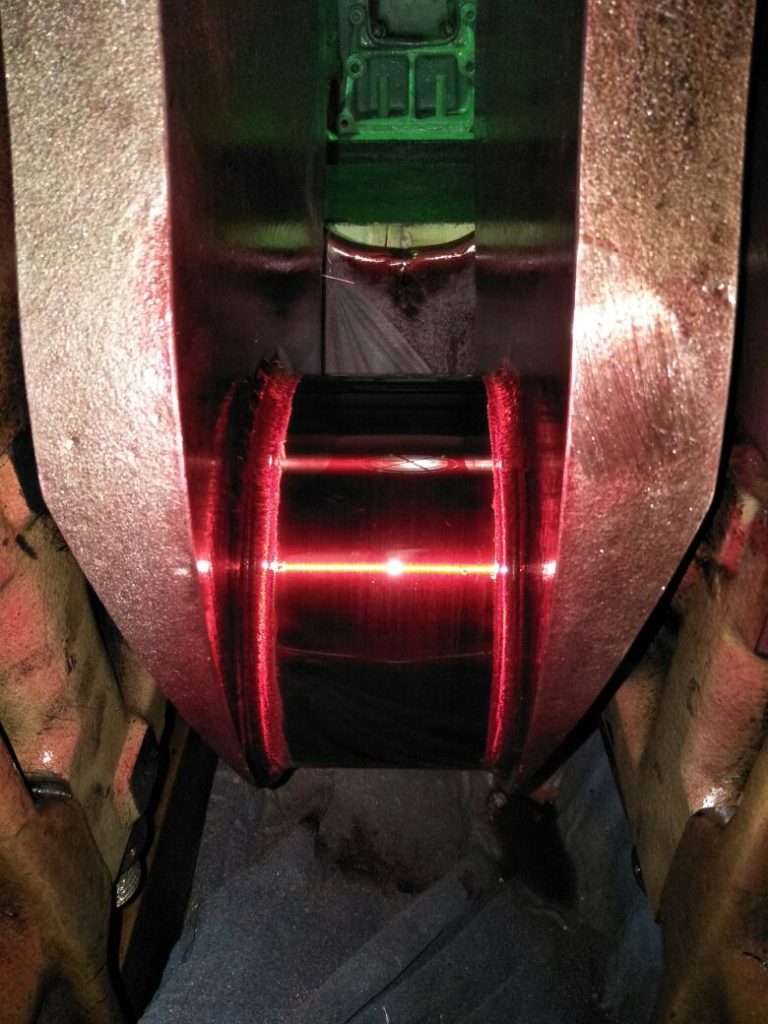

RA Power Solutions undertakes complete reconditioning of the crankshaft of marine engines, diesel generating sets, compressors, forging hammers, and all other applications. The crankshaft repair is undertaken onsite without removing the crankshaft from the crank casing. This saves the downtime of the equipment and the cost of assembly of the engine after the crankshaft repairs are executed. Companies are opting for on-site repair of the crankshaft, and sending the crankshaft to the workshop for repair is outdated.

The following procedure is adopted by our experienced engineers for calibration:

Before starting the repair of the crankshaft, crank pin, and main journals is subject to the following inspection:

- Crankpin and main journal are measured for the presence of taper and ovality.

- The alignment of the crankshaft is checked by deflection.

- Radius fillets and lubricating oil holes are inspected for their original profile.

- Inspection of hardness

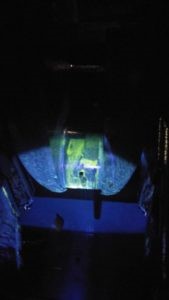

- Crack detection by MPI/Ultrasound and dye penetrant test.

- Checking of surface finish

- Visual inspection of the counterweight and counterweight bolts. In case of an accident, crack detection by MPI is recommended.

Based on the above observations, the crankshaft is repaired onsite, maintaining the following parameters:

- The grinding of the crankpin and the main journal is undertaken as per the undersize recommended by the manufacturers and the availability of the bearings with the engine manufacturers.

- Preparation of radius fillet, lubricating oil hole, and maintenance of profile as the original.

- Polishing the crank pin and main journal, maintaining the surface finish as per international standards.

- Checking of hardness and crack detection test after repairs are executed.

We have a team of experienced technicians and the necessary instrumentation to undertake the repair of the crankshaft on board a vessel, even while sailing or for stationary engines.

All the crankshaft repairs, onsite crankshaft inspection, and onsite machining services undertaken by RA Power Solutions are guaranteed to provide satisfactory performance.

The author of the blog is Mr. Raj Shahani, Managing Director of the company. He has 45 years of experience in providing services related to engine repair and overhauling, crankshaft grinding and polishing, crankpin reconditioning, and many more.

For any queries regarding crankshaft grinding for industrial and marine applications, crankshaft regrinding and compressor large engine, crank grinding, main journal crankshaft grinding, crankshaft grinding machine manufacturer, on-site grinding, onsite machining, onsite crankshaft grinding, onsite crankshaft inspection, and onsite machining services, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131,+91 9810012383.