Reduce Cost And Breakdown Time By Onsite Repair Of Crankshaft

The failure of the crankpin and main journal bearing causes serious damage to the crankshaft, which is as follows:

- Development of excessive taper and ovality in Crankshaft, Crankpin, and Main Journal.

- Development of a crack

- Abnormal increase and decrease in hardness

- Loss of alignment of the crankshaft, increasing deflection readings.

- Development of bearing line marks, pitting, and local depression

- Damage to the radius fillet and lube oil profile

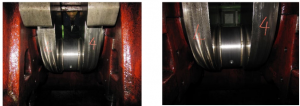

The onsite crankshaft grinding equipment developed and manufactured by us is capable of undertaking the grinding and polishing of the crankshaft in one setting. The tolerances after crankshaft repair are strictly maintained as per the manufacturer’s specifications.

We have a highly trained and skilled team of technicians who are deployed to the plant site or on a vessel in the shortest possible time. The process we follow for repairing the crankshaft is faster, more cost-effective, and more convenient. It, of course, avoids the removal of the crankshaft and transport to the workshop.

The repair of the crankshaft , onsite repair of crankshaft was executed by RA Power Solutions Pvt. Ltd is approved by leading inspection agencies, including Lloyds, DNV, and many other inspection agencies. For more information, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.