A reliable crankshaft is the heart of every engine, from marine diesels to heavy-duty industrial power plants. Traditionally, repairing a worn or damaged crankshaft meant removing it from the engine, transporting it to a workshop, and waiting days or even weeks for precision machining. This outdated process not only delays operations but also adds unnecessary cost and risk of damage during handling.

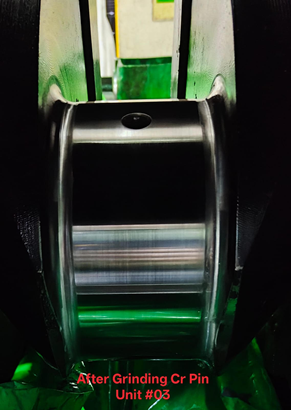

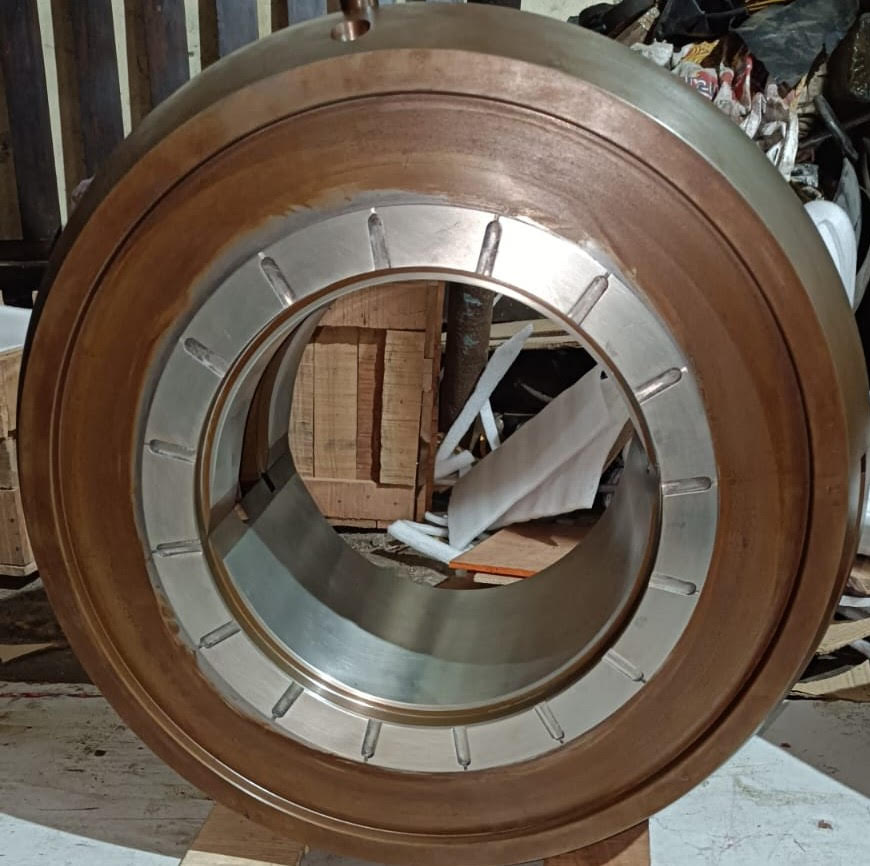

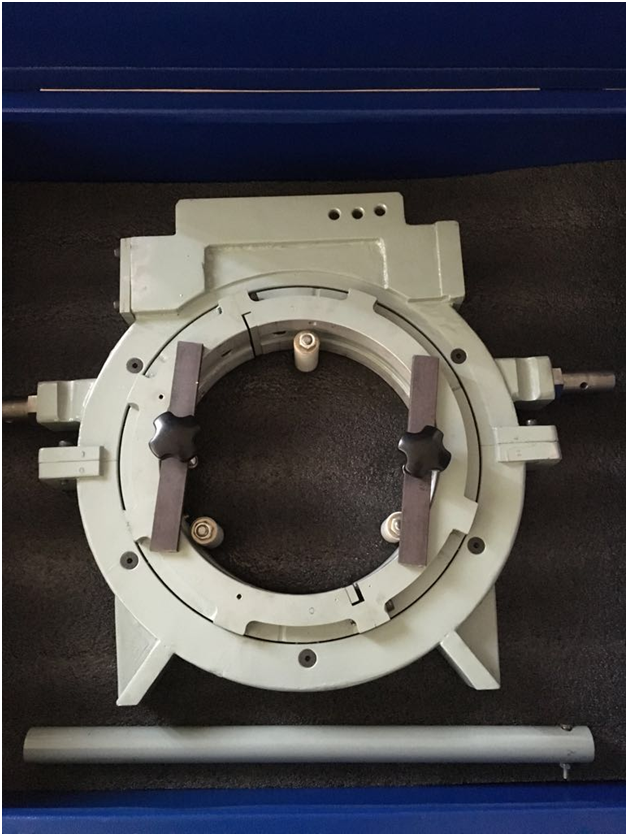

Today’s solution is a portable crankshaft grinding machine that lets technicians restore crankshaft journals and crankpins directly on site, without removing the crankshaft from the engine block. This onsite approach can truly transform your workshop overnight.

What Makes Portable Crankshaft Grinding Machines a Game-Changer?

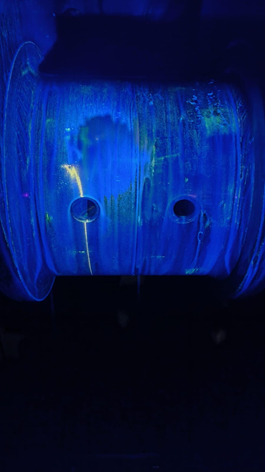

- Onsite Precision Grinding: Modern crankshaft grinding machines can be transported easily and operated right where the engine sites, whether on a vessel at sea, in a power plant, or in a remote engine room. This eliminates the need to dismantle, transport, or reassemble heavy engine components.

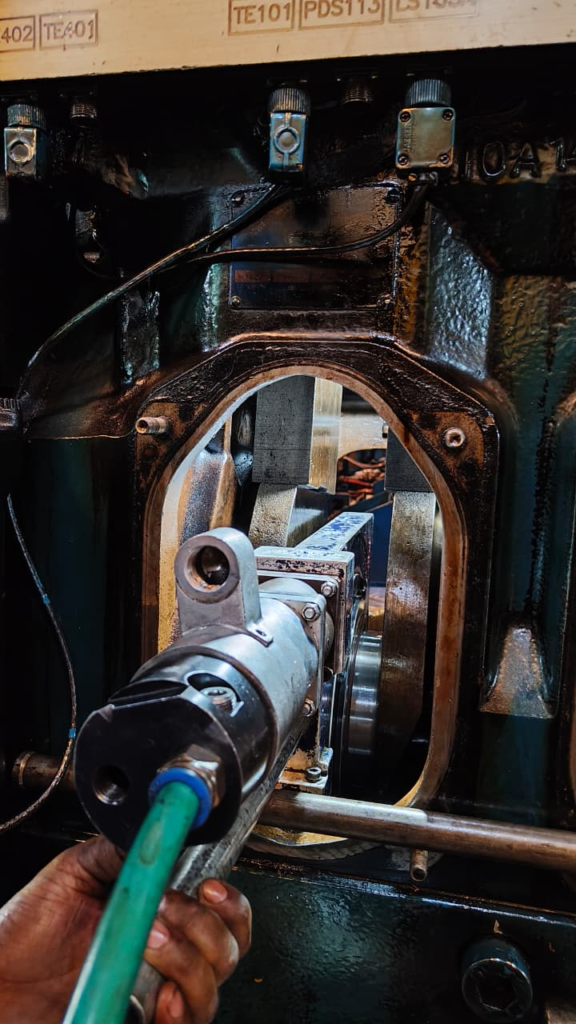

- Lightweight, Easy to Operate: Designed with portability in mind, these machines are lightweight and simple to use. Technicians can quickly set up the grinder through engine inspection ports and restore crankpin or main journal surfaces with precision.

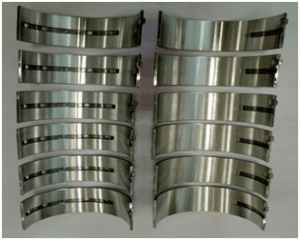

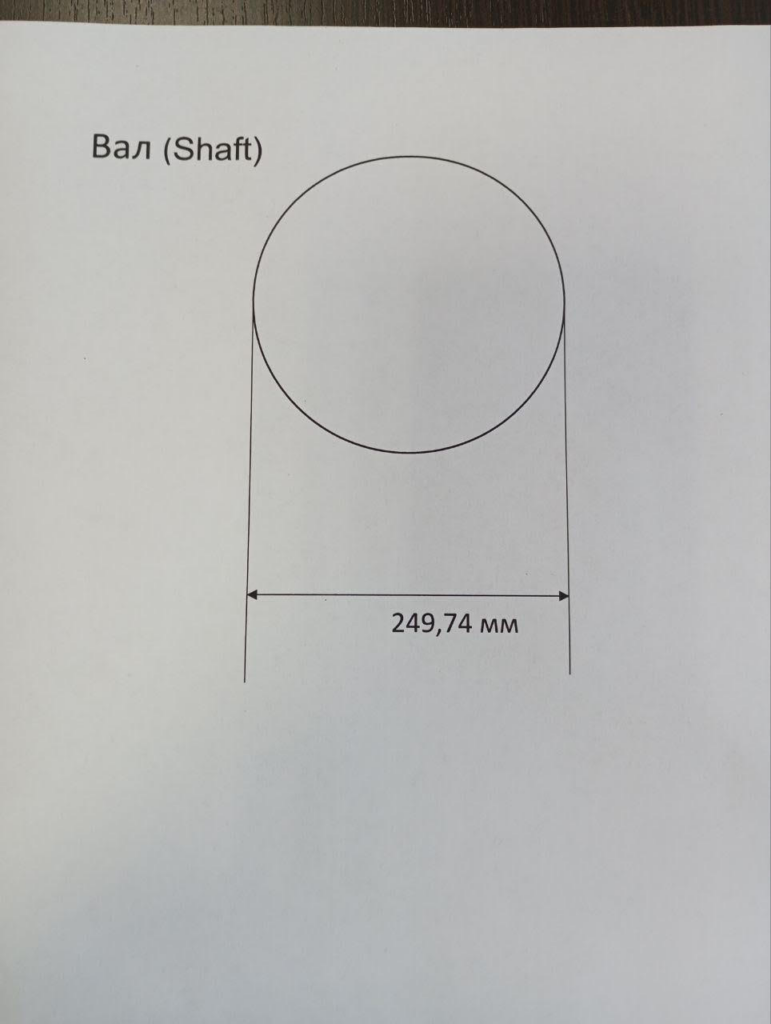

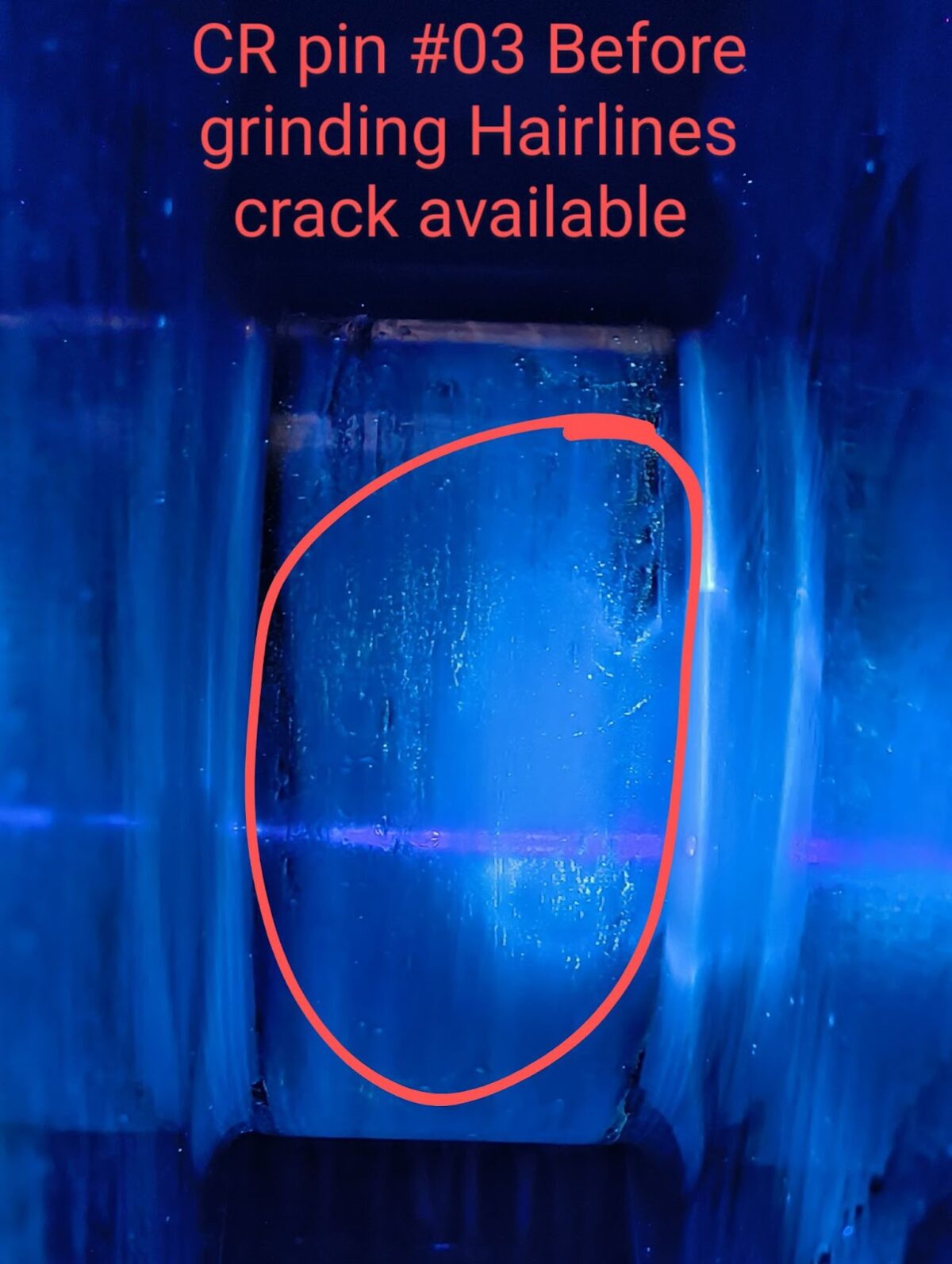

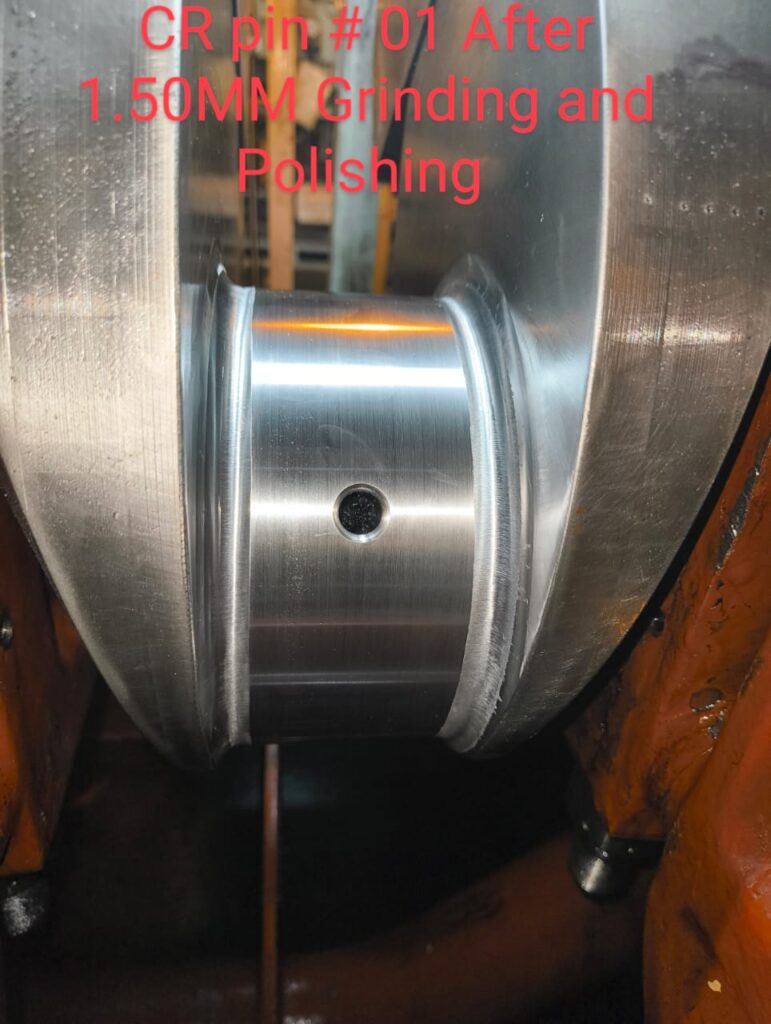

- Maintains OEM Tolerances: The latest onsite crankshaft grinders control critical parameters like taper, ovality, surface finish, and run-out, ensuring journals are reliably restored to OEM specs without compromising performance or reliability.

- Minimal Downtime: Traditional workshop repairs can keep an engine offline for days. Portable onsite machines reduce downtime significantly, essential for marine fleets, industrial plants, and mobile service providers needing quick turnaround

- Quality & Reliability Backed by Engineering: Manufacturers like RA Power Solutions use high-grade materials (such as vibration-dampening titanium steel) and maintain strict quality controls, ensuring the equipment performs consistently even under operational conditions.

Benefits You’ll Experience

- Cut repair time drastically

- Save cost on transportation and workshop labor

- Increase engine uptime and availability

- Empower your team with skill and equipment

- Quick ROI, often recouped within 2–3 repair cycles

Investing in a portable crankshaft grinding machine equips your facility with the capability to handle crankshaft servicing in-house and stay ahead of competition.

Introduction to R A Power Solutions’ Crankshaft Grinding Machine:

RA Power Solutions’ onsite grinding machine has transformed crankshaft repair. It can grind crankshafts while they are still in the block. This portable equipment enables technicians to travel the world and perform repairs on-site.

For more information on portable crankshaft grinding machines, onsite grinding of crankshafts, crankpin machines and main journal grinding equipment, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

A machine designed to grind and restore crankshaft journals and crankpins directly onsite, without removing the crankshaft.

It eliminates the need to dismantle the engine or send components to external workshops, dramatically reducing downtime.

Modern machines typically cover crankshaft diameters from small engines up to around 700 mm or more.

Yes, these machines control tolerances like surface finish, ovality, and taper to meet original manufacturer specifications.

Most suppliers offer onsite or workshop training to ensure operators can set up and run the machine effectively.