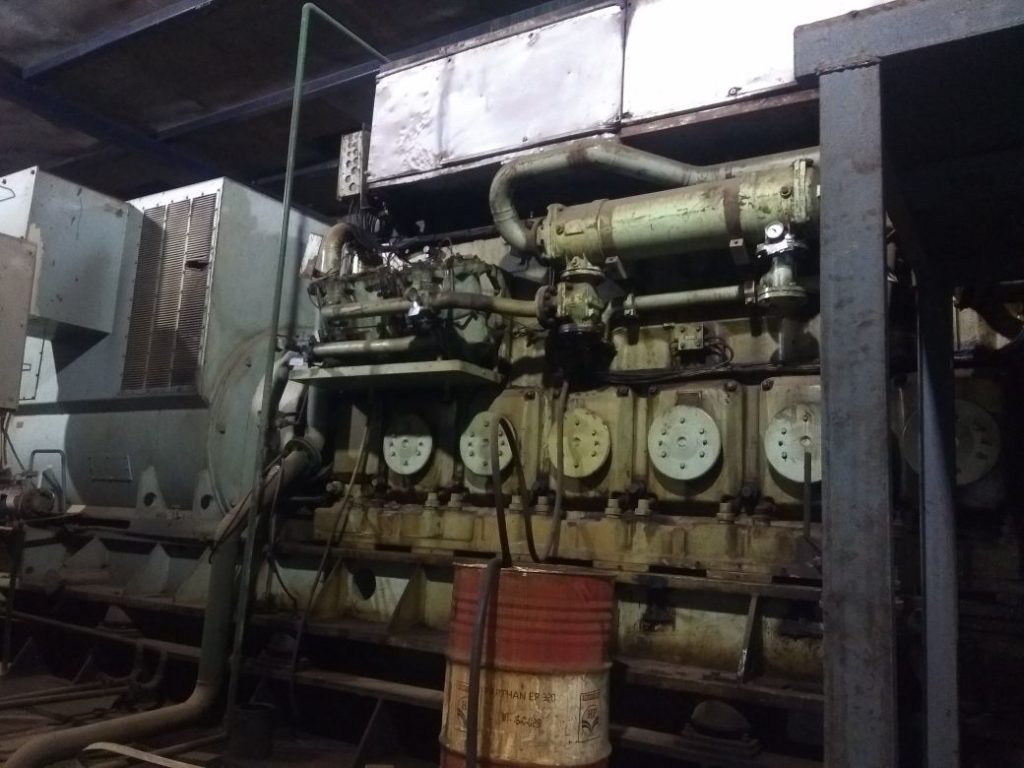

RA Power Solutions has been extending services related to crankshaft repair, metal stitching, rebabbling of bearings, overhaul, and maintenance of high-capacity engines all over the world. The concept of crankshaft repair changed with time. The use of a bench-type crankshaft grinding machine is now completely outdated, and onsite crankshaft repair and grinding machines are used all over the world to repair crankshafts onsite and crankshaft grinder manufacturer in any part of the world. There is no requirement for the removal of the crankshaft, packing, and transporting it to the designated workshop.

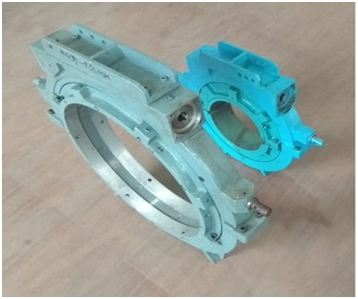

RA Power Solutions is a crankshaft grinder manufacturer, manufacturer of portable, lightweight Main Engine and auxiliary engine repair machines for the last 15 years from the range of 35 mm to 700 mm in terms of diameter.

The typical application of an onsite or in situ crankshaft grinding and polishing machine is as follows:

- Pump crankshaft

- Forging Press Crankshaft

- Diesel Engine Crankshaft

- Four-stroke stroke/2 two-stroke main engine and auxiliary engine crankshaft

- Turbine shaft, fan shaft, tail shaft, alternator shaft, cylindrical shaft, etc.

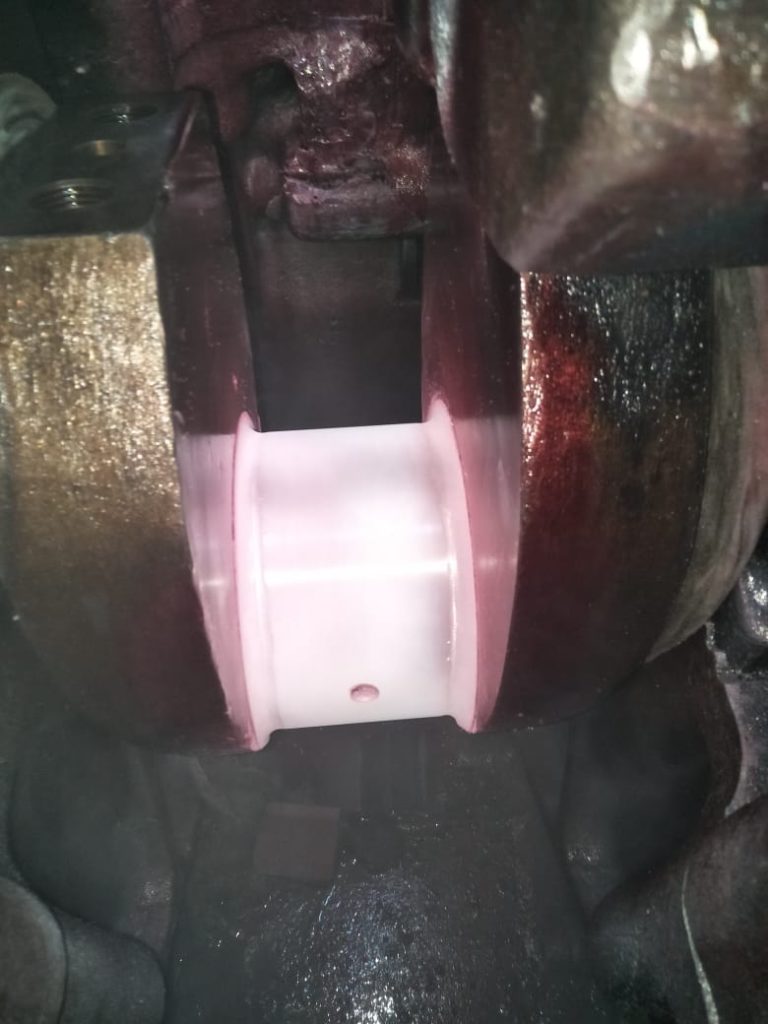

The in situ crankshaft grinding machine is designed to maintain similar tolerances as bench-type crankshaft grinding machines. All the parameters, specifications, and tolerances that are specified by the engine manufacturers can be easily maintained.

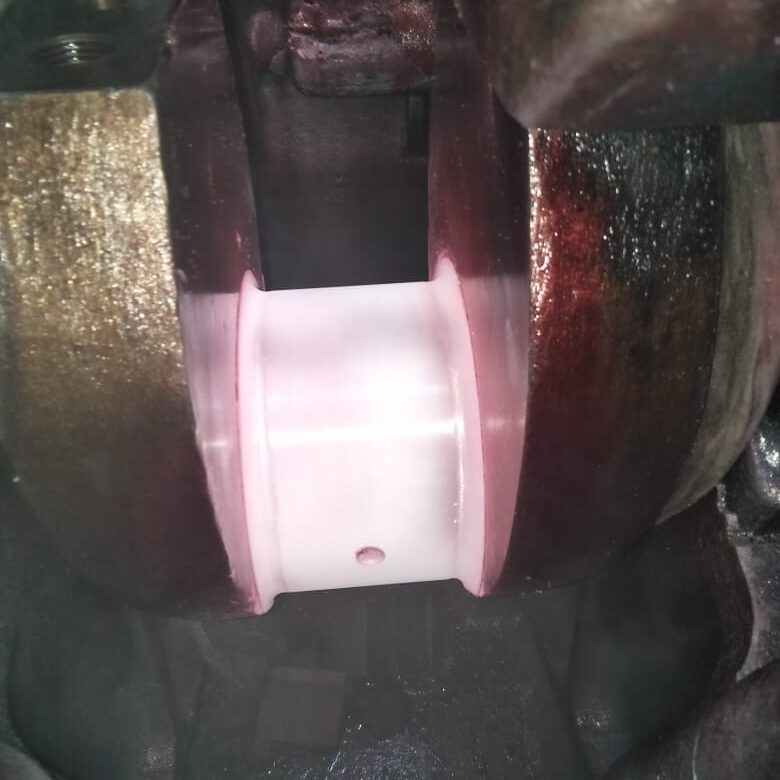

Some of the main features of the crankshaft, Main Engine, and Auxiliary Engine Repair Machine are as follows:

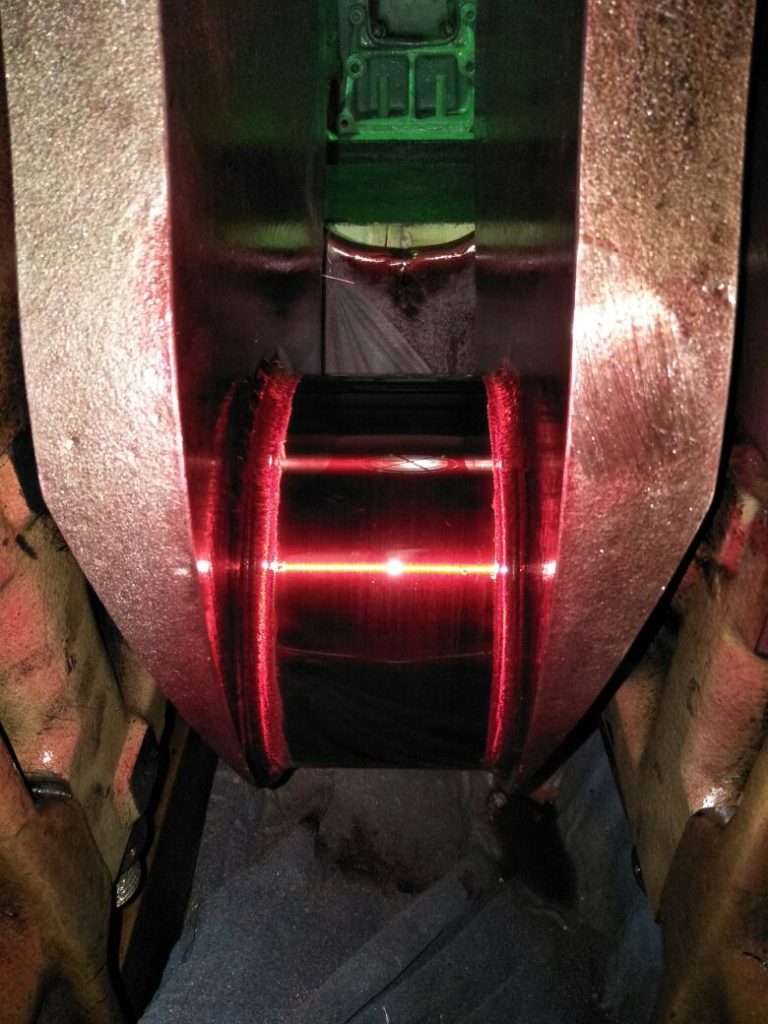

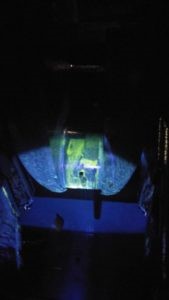

- Grinding and polishing of the crankshaft is possible onsite with this onsite repair equipment.

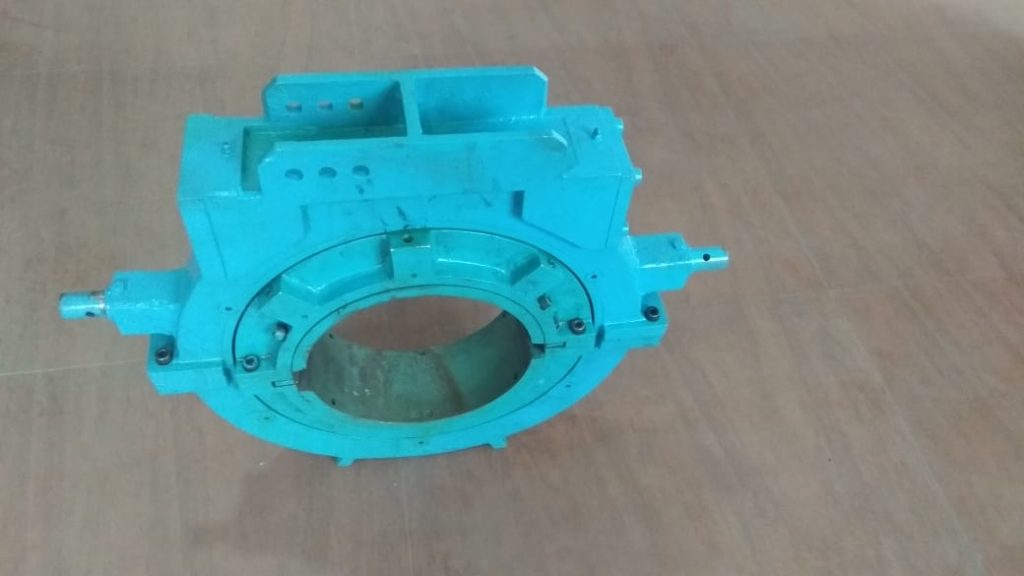

- Crankshaft repair & grinding machine is compact and can be inserted from the limited space available from the inspection window of an entablature.

In case of space constraints machine can be redesigned and modifications can be undertaken to place the machine on the crank pin from the window. In situ, the crankshaft grinding and polishing machine is capable of maintaining taper, ovality, and surface finish strictly as per the manufacturer’s tolerance. Easy to operate.

- Free 1-week training is provided onsite or in the training center of RA Power Solutions.

- In situ crankshaft repair and grinding machine is available in the range of 35 mm to 700 mm. More than 70 crankshaft grinding machines are supplied all over the world.

- With this precise Main Engine and Auxiliary Engine Crankshaft Repair Machine, it is possible to repair the crankshaft while sailing the vessel. This is possible due to the design and construction of the machine.

RA Power Solutions is a renowned crankshaft grinder manufacturer and exporter, offering top-notch solutions in the power industry. With their cutting-edge technology and extensive expertise, they have established a reputation for delivering high-quality crankshaft grinding machines.

This blog is written by Mr. Raj Shahani (Managing Director of RA Power Solutions). He has forty-five years of experience in the field of engine repair. He has developed an onsite crankshaft grinding machine after extensive research and trials. All the crankshaft grinding machines sold by us all over the world are performing satisfactorily.

For any queries related to high-capacity diesel engines, insitu grinding machine supplier, main engine maintenance, engine crankshaft grinding machine, drop us an email at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.