RA Power Solutions has been working on high-capacity diesel engine overhaul, repair, and maintenance, and grinding of crankshafts for the last 45 years. During our work on engines on board a vessel or in large engineering plants, we have observed that the incidents of crankshafts getting damaged due to accidents are becoming increasingly often.

As we are aware that the crankshaft is the heart of the engine. Using the connecting rod, the crankshaft converts reciprocating motion to linear movement, which drives the engine. RA Power Solutions has the process, technology, and onsite crankshaft grinding machines ranging from 35 mm to 700 mm, and crankshaft repair is now possible without disassembly of the crankshaft from the engine. The repair of the crankshaft is possible irrespective of its length and weight, as we have the equipment available up to 700 mm in terms of diameter.

The crankshaft, in general, has various applications, including diesel generating sets and marine engines. Typical areas of crankshaft applications are as follows:

- Compressors

- Railway vehicles/engines

- Power generators

- Forging hammers

- Pumps

- Marine engines, etc.

The crankshafts of high-capacity engines used for marine and land-based applications are of forged steel. RA Power Solutions has experienced technicians and advanced technology equipment, i.e., an in situ crankshaft grinding machine. To maintain the dimensions and tolerances strictly as per the manufacturer’s specifications and recommendations.

Major parameters maintained after crankshaft grinding and repair and grinding of the crankshaft, are as follows:

- Taper and ovality can be maintained within 0.02/0.03 mm or less as per the requirement of the engine manufacturer.

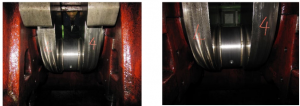

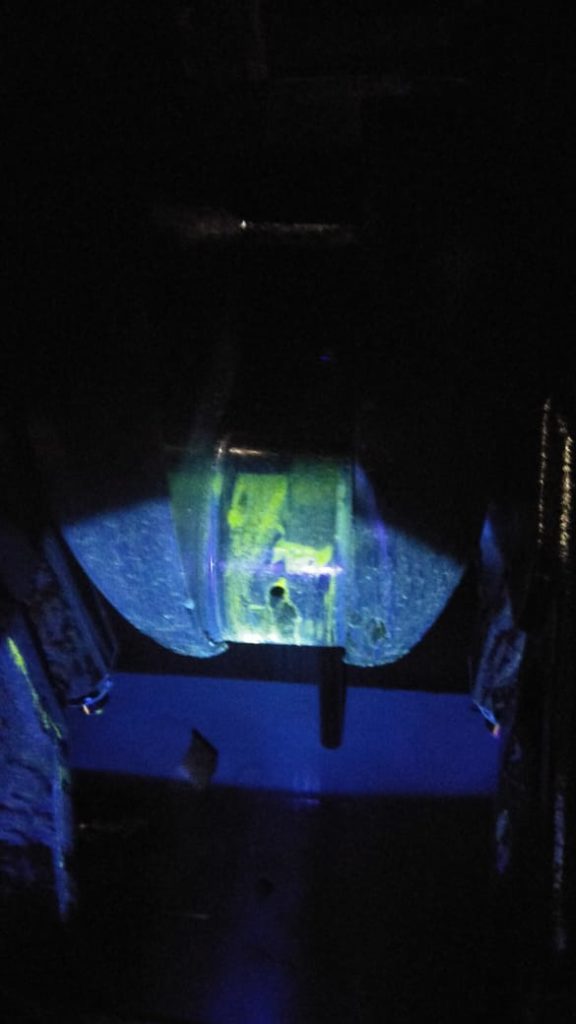

- The portable in situ crankshaft grinding machine used by RA Power Solutions. The technicians are capable of maintaining a surface finish of far less than 0.03 RA value.

- The high surface finish achieved after grinding the crankpin and main journal diameters significantly improves performance. It enhances the life of the connecting rod and main bearings.

- The radius profile of both the end of the crankpin or main journal and the lubricating oil profile is maintained strictly as per the original profile.

- The straightness/runout of the crankshaft is checked, and the crankshaft is straightened if required by the peening process.

- Counterweight can be replaced in case of damage, and supporting threads are repaired onsite.

During our work of more than four decades, we have repaired more than 10,000 crankshafts used for different applications. All the repairs are executed with a guarantee. We are an ISO-certified company and also meet the standards requirements like DNB, Lloyd’s, etc. All our technicians possess Indian CDC and can join the vessel in a short time in any part of the world.

Crankshaft grinding and repair are essential processes in the field of engine maintenance and precision engineering. The crankshaft, being a crucial component in any engine, requires meticulous attention to ensure its optimal performance. At RA Power Solutions, we specialize in main bearing machining, grinding of crankshafts, and in situ crankshaft grinding.

For more information regarding in situ crankshaft inspection, in situ grinding crankpins, and cost-effective crankshaft grinding in Dubai, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.