Crankshaft journal and crankshaft crank pin diameter should be grind and polished to attain a surface finish of 15 microinches or better. Again, the maintenance of taper and ovality of crankpin and crankshaft main journal has to be within the limit recommended by the manufacturer. Generally, the limits are within 0.02 to 0.05 mm, depending on the diameter of the crankpin and main journal. Till few years back it was a monopoly of few European companies undertaking onsite crankshaft grinding and crankshaft polishing jobs charging exorbitant prices from the shipping companies and the power plants who had no option but to get the job of onsite crankshaft grinding and crankshaft polishing done from them.

RA Power Solutions have been extending crankshaft grinding, crankshaft polishing, maintenance, and repair of high-capacity engines for the last forty years. Out of our experience, we have developed and manufacture onsite crankshaft grinding and crankshaft polishing machine having the range from 30 mm to 700 mm. The onsite crankshaft grinding machine has brought down the cost of repair of crankshaft and have broken the monopoly of the European service providers. The onsite crankshaft grinding machine manufactured by RA Power Solutions has the following features:

- The onsite crankshaft grinding and polishing machine is portable, lightweight, and can be easily taken to the site all over the world.

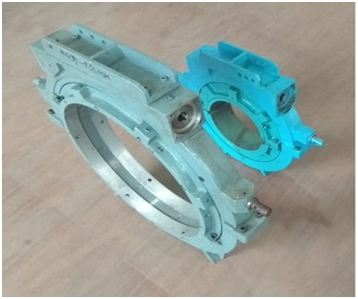

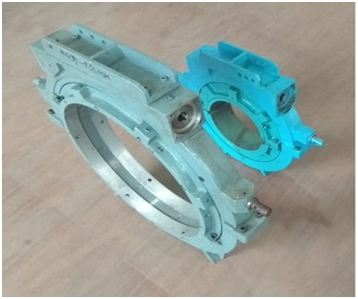

- The crankshaft grinding & polishing machine is portable and can be inserted from the inspection window. The crankpin grinding and polishing can be done without removing the crankshaft from the engine block.

- The machine is designed and manufactured as per the customer’s requirement. For example, We have supplied machines for the crankshaft having a small bearing width or limited space.

- The crankshaft grinder machine is capable of maintaining taper and ovality of crankpin or main journal as per the tolerances stipulated. It can achieve even a close tolerance of 0.01 mm in terms of taper and ovality. Surface finish far better than the international standard is achievable.

- The onsite crankshaft grinding and crankshaft polishing machine is easy to operate and maintain. Onsite training by our experienced technicians is provided.

- The cost of the crankshaft grinding and crankshaft polishing machine is low and affordable.

We have sold more than 70 crankshaft grinding and crankshaft polishing machines all over the world to leading drydocks, shipping companies, diesel power plants, repair workshops, etc.

The author is Mr. Raj Shahani, Managing Director of the company. He is having 40 years of experience in grinding of crankshaft, polishing of crankshaft, and all services related to repair of engines and supporting equipment. He has designed and developed the portable crankshaft grinding machine to save time and money.

We will be pleased to share more information regarding onsite crankshaft grinding machine, onsite crankshaft grinding and polishing machine, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.