RA Power Solutions is known as a leader in offering onsite repair of crankshaft worldwide with forty years of experience in this field, the company’s endeavor is always to save the Crankshaft from rejection.

The crankshaft meets with serious accidents and are even rejected by the European Repair Companies attended by RA Power Solutions and is successfully repaired. This is possible because of having technicians who have hands-on experience in repairing more than ten thousand crankshafts.

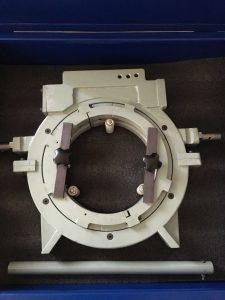

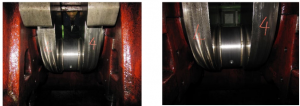

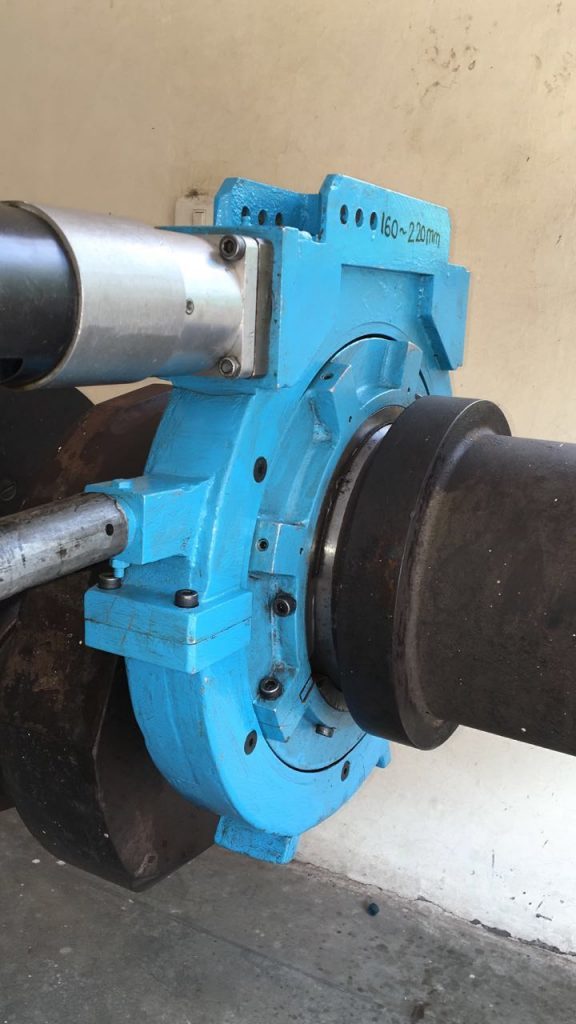

All crankshafts are initially checked and inspected to ensure that they are acceptable for reuse or for repair. The onsite crankshaft grinding and crankshaft polishing is undertaken through the window of the engine block. Due to continuous innovation in the design and technology of crankshaft grinding machines manufactured and used by us, it is possible to maintain the dimensional tolerances strictly as per the original equipment manufacturer. The crankshaft grinding and polishing are done in the minimum possible time. Thus, reducing the breakdown time of the equipment considerably.

Presently, we are undertaking crank-pin and main journal grinding and repair up to 700 mm and are in the process of increasing the capacity up to 1000 mm. We undertake onsite crankshaft grinding of all popular makes of engine and their model. Few of them are as following-

Wartsila 6R32, 12V32, 18v32, Mirrlees Black Stone ESL, MAJOR K series Generators, Ruston, Allen, Yanmar, MAN B&W, Daihatsu engine, etc. For more details on the marine crankshaft repair, crankshaft grinding machine, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.