Onsite Metal Stitching and Metal Locking for Repair of Cracks

Cracks in cast iron are developed due to excessive stress beyond its tensile strength or due to accidents. The heat-related cracks, and cracks due to impact are quite common in case of engine blocks, casing of turbocharger, compressors and mechanical equipment.

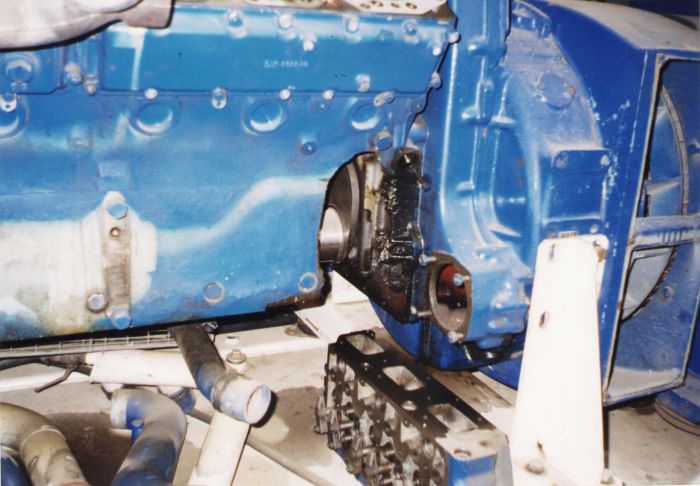

The repair of cracks in cast iron has been tried by the different process and methods, especially in case of cracks in the engine block. The welding process for the repair of the cracks is not always successful due to excessive heat generated. It is observed that even the center line of main journal housings gets disturbed and looses alignment.

RA Power Solutions undertakes repair of cracks by cold process i.e. metal locking and metal stitching. The metal lock and metal keys are sourced strictly as per the metallurgy of the broken casting and are inserted in a specific process.

It is observed that the repair of cracks by metal stitching process is successful in comparison to conventional welding method.

Onsite metal stitching and metal locking is done by our skilled engineers. This is of great advantage to the end user as it reduces the downtime.

RA Power Solutions has Four decades of experience in undertaking repair of cracks by metal stitching process. Repair of following damaged castings have been successfully undertaken.

- Metal stitching of engine block (Wartsila, MAN, Mirrlees Blackstone, Daihatsu).

- Repair of turbine casing of turbocharger.

- Onsite repair of pump casing by metal locking.

- Metal stitching of forging press.

- Metal locking of cracked cement, power, chemical, sugar plants machinery.