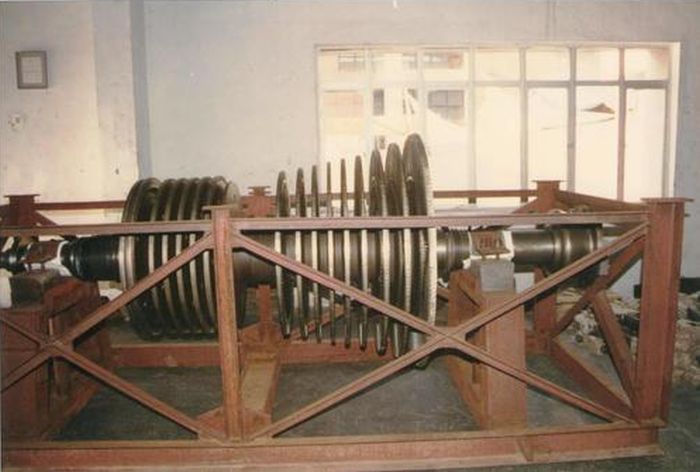

In case of a turbine the rotor shaft is an important part which is forged steel as per the designing parameter of the main equipment. The periodical inspection of rotor shaft mainly the bearing sitting area is of great importance. It is observed that the surface roughness or line marks are developed. In certain cases taper and ovality also increases. RA Power Solutions extends services for onsite polishing of rotor shaft. The polishing is undertaken by light weighted, portable rotor shaft grinding and polishing machine. After polishing the bearing line marks, pitting and the rough surface are removed provided the diameter remains within the tolerances.

RA Power Solutions undertakes onsite grinding of rotor shaft up to 700 mm in diameter. The process of onsite grinding and polishing of rotor shaft is successfully proven. We have executed more than 800 jobs of onsite repair of rotor shaft worldwide.

RA Power Solutions design, develop and manufactures onsite rotor shaft grinding and polishing machine. These grinding and polishing machines are very easy to operate and are competitively priced. We also extend on job training to the client.

Contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383 for more details.