Onsite Rotor Shaft Grinding and Repair

In industry and power generation plant, turbines are running continuously. The rotor shaft which is supported on white metal Babbitt bearing gets worn out developing taper, ovality, bearing line marks and damage to the white metal Babbitt bearing.

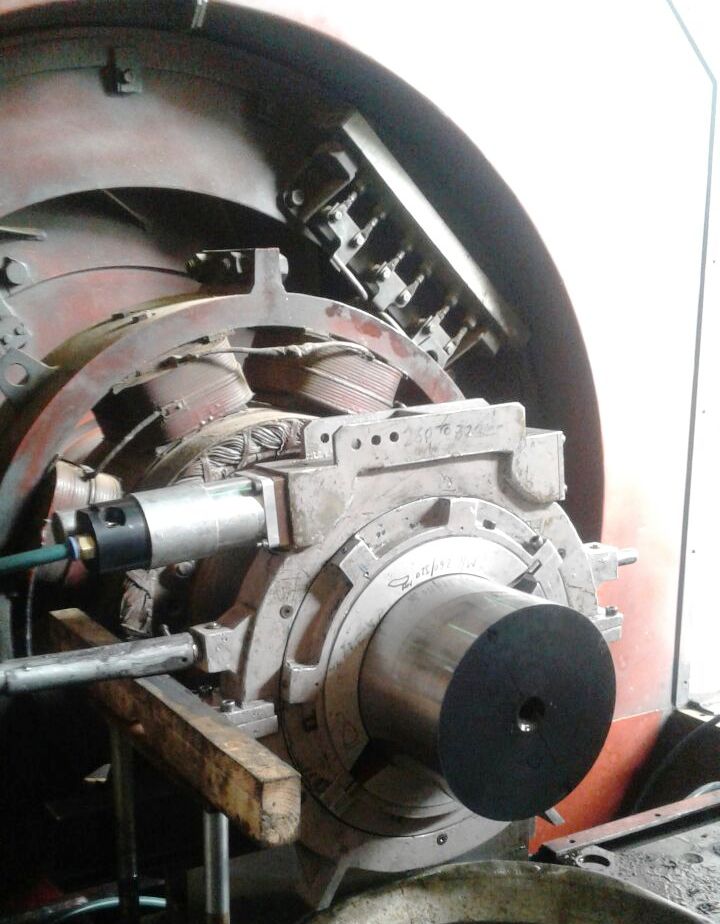

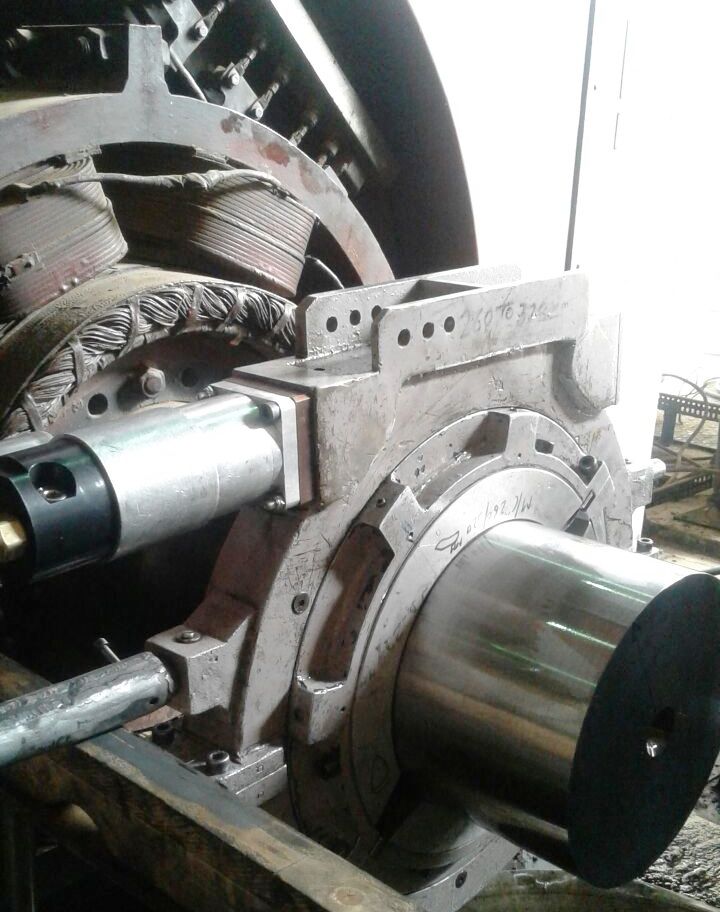

RA Power Solutions undertakes on site repair of rotor shaft bearing sitting diameter. There is no requirement of disassembly of rotor shaft. The rotor shaft diameter is dimensionally checked by experienced engineers. The hardness and crack detection test is also undertaken, which is of great importance. The grinding of rotor shaft diameter is undertaken by portable rotor shaft grinding machine. The tolerance within 20 microns is achieved with a requisite surface finish. We have facilities to undertake rotor shaft grinding and polishing up to 700 mm diameter. We work in two shifts of 12 hours each to reduce the downtime.

We also design and manufacture rotor shaft grinding machine as per site requirement up to 700 mm and have sold more than 60 machines all over the world.

RA Power Solutions recently successfully repaired 160 MW rotor shaft of a turbine installed in a leading cement plant in North India. The plant owners have a major challenge of keeping aging turbines up and running efficiently and cost effectively. Matching white metal Babbitt bearings having bore size of 430 mm were also supplied.

We specializes in the meticulous refurbishment of rotor shafts and repair of rotor shafts, setting the industry standard with our expertise and cutting-edge techniques. With an unwavering commitment to precision and quality, we restore worn-out rotor shafts to their original specifications, enhancing performance and extending the lifespan of critical machinery. RA Power Solutions stands as a trusted partner for industries reliant on seamless machinery operation, offering comprehensive solutions that optimize efficiency and reliability through their unmatched refurbishment of rotor shafts and repair of rotor shafts services.

For more information, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.