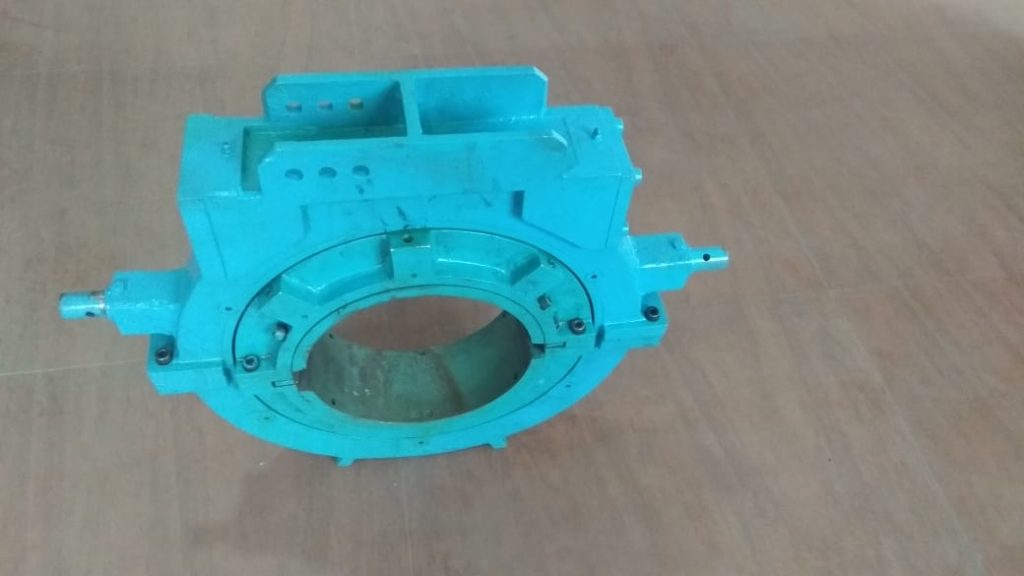

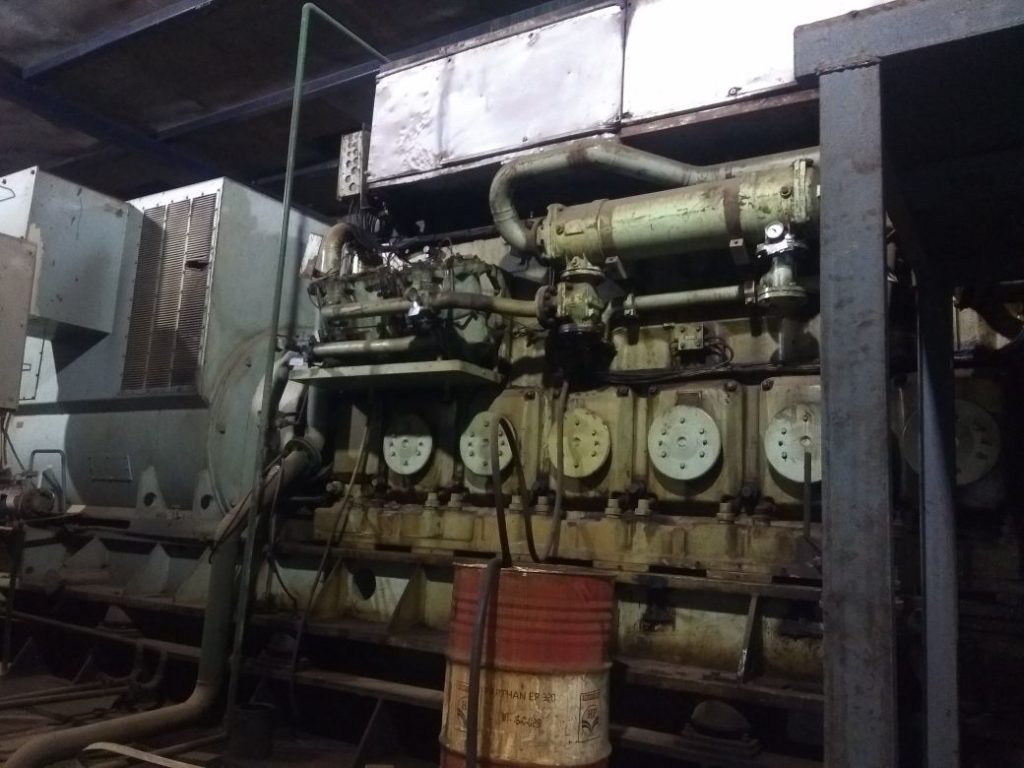

Crack in cast iron components or damage of casting now can be easily repaired by metal lock and metal stitching process. The crack repair technology by metal lock and metal stitching process has outdated the old conventional method of crack repair by welding. It is said that crack repair by metal stitching and metal locking process is perhaps the only method to repair cracks in cast iron and to save the large, expensive components from rejection. In some cases, it is observed that the parts get more damaged by the welding process, resulting in the ultimate rejection and heavy financial losses.

More Details Of Repair Cast Iron Stitching | Cast Iron Repair And Cracked Engine Block Repair

Cast Iron Stitching repair in case of development of cracks or damage, casting is best undertaken by metal stitching and metal locking process. We undertake cast iron crack repair which has the following main advantages:-

- Cast iron repair is possible onsite by metal stitching and metal locking process.

- We extend our services 24*7 through our experienced technicians dedicated for repair cast iron, aluminium casting and cast steel casting by a metal lock.

- Downtime is drastically reduced as there is no requirement for the disassembly of damaged components.

- Crack repair in cast iron and repair of damage casting by metal locking is far more cost-effective in comparison to the purchase of new and expensive parts.

|

|

|

Advantages of Crack Repair | Damaged Cast Iron Component by Metal Stitching & Metal Lock:

- No need of disassembly of equipment, pack it, and send it to the workshop for repairs.

- Onsite crack repair is possible as the tools used are lightweight and can easily be taken to the site.

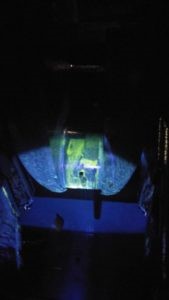

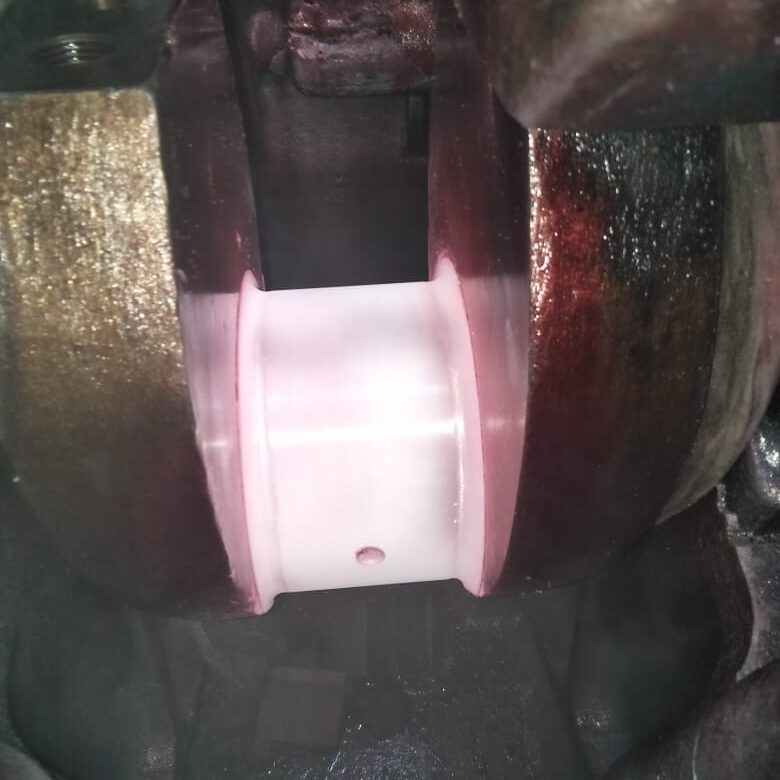

- In case a large portion of cast iron components is damaged into pieces, it is possible to replace the damaged area by the new cast piece which is metal stitched with the parent casting.

- Metal stitching and metal locking is proven to be a permanent crack repair process. RA Power Solutions executes all crack repair assignments with a guarantee.

- Cold process, no heat is generated, no loss of profile. Hence, no machining is required.

- Repair undertaken onsite. Hence, downtime of the plant is reduced drastically.

- Repair is possible, qualifying for water-tight and gas-tight.

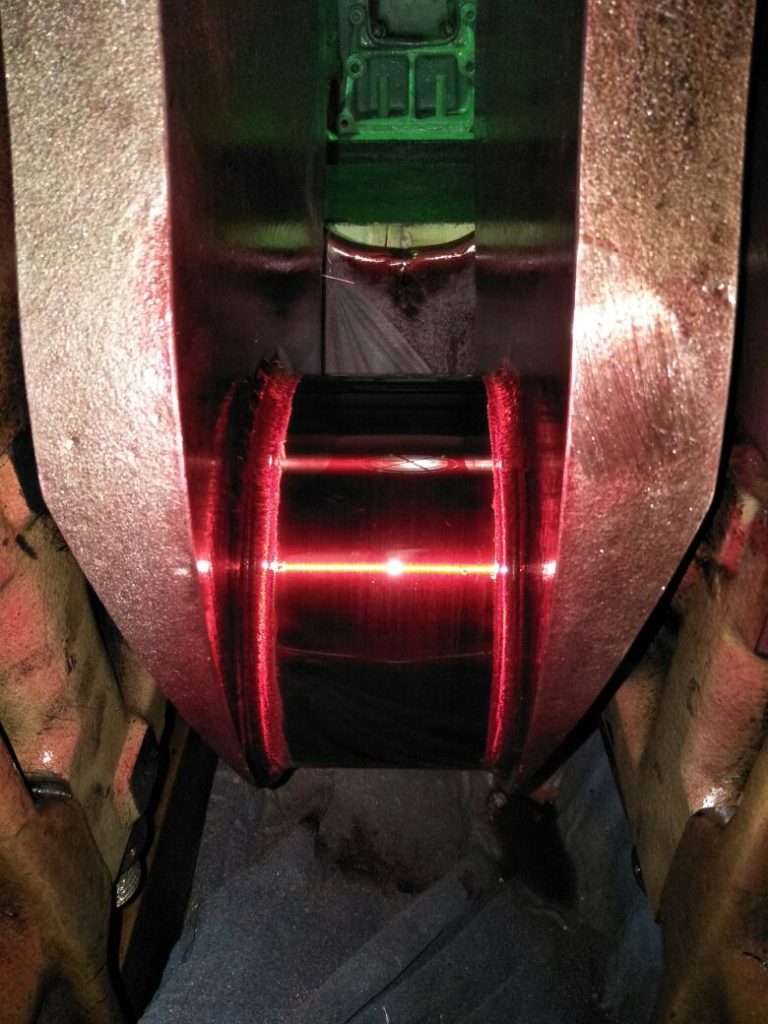

|

|

|

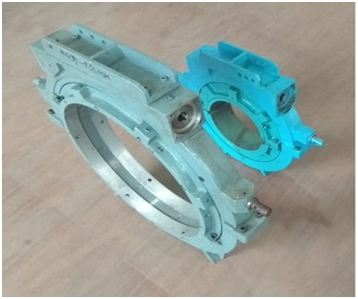

RA Power Solutions have been undertaking the lock and stitch engine block repair and cracked engine block repair of cast iron and aluminum components by metal stitching and metal locking for the last forty years. We have expertise in replacing the damaged large area of casting with a new piece. Thus maintaining the original strength of the component. In most of the cases, the new casting is dispatched from our workshop maintaining the same internal and external profile and projections after repair by metal stitching and metal locking process it is even difficult to make out whether the area was damaged as no sign of damage are visible.

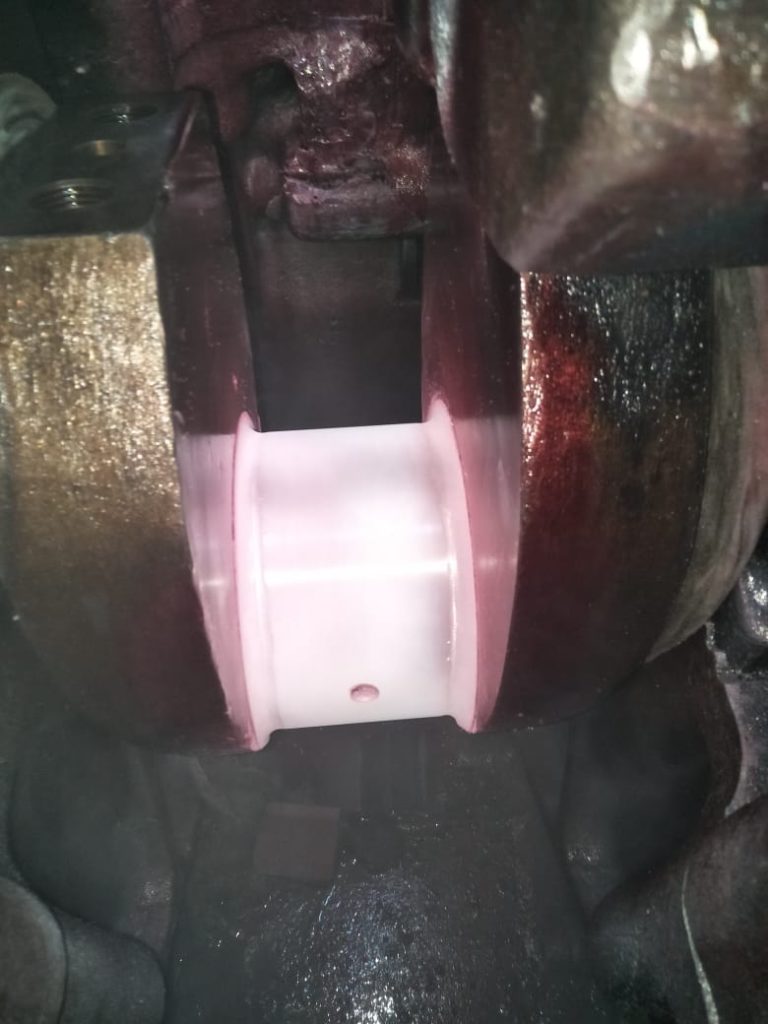

|

|

|

The cost of repairs is very important in this time of global recession. RA Power Solutions is considered to be the most economical company executing repairs all over the world. Our technicians can travel to any part of the world in a short notice and can also execute the repairs while sailing of the vessel.

For more information on metal stitching cast iron, cracked engine block metal stitching, cast iron engine block repair, cracked engine block repair, repair of crack cast iron, metal crack stitching, lock and stitch cast iron repair, metal stitching of engine block, metal crack repair, engine block repair, engine block stitching, cold metal stitching engine block, cast iron block repair, repair of crack in cast iron casting, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 and +91 9810012383.