RA Power Solutions is the first company to introduce portable, lightweight, onsite crankshaft grinding and crankshaft polishing machines, crankshaft polishing tools, and crankshaft repair machines at the lowest price.

With the introduction of a revolutionary onsite crankshaft grinding machine, now it is possible to save the repair cost of the crankshaft. The onsite crankshaft grinding repair machine has proven its worth with 70 clients based all over the world.

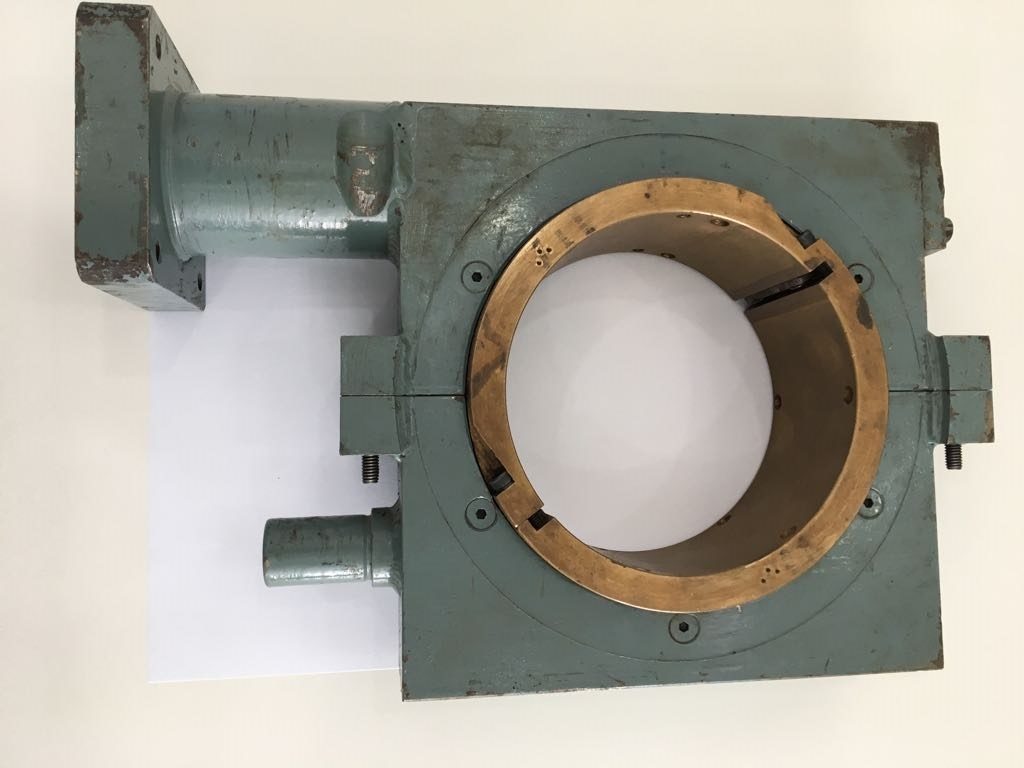

The onsite Crankshaft Grinding Polishing Machine has the following features:

- Onsite crankshaft grinding polishing machine can undertake crankshaft grinding and crankshaft polishing up to 700 mm diameter without dismantling the crankshaft.

- In terms of taper and ovality tolerance can be maintained within 20 to 30 microns or as per the manufacturer’s requirement.

- For the long life of bearings and crankshaft it is important to have a high level of surface finish with onsite crankshaft grinding polishing machine it is possible to maintain a surface finish of 0.15 RA value.

- The onsite crankshaft polishing machine is easy to operate and job training is also provided.

- Onsite Crankshaft Grinding Polishing Machines can be carried as a accompanied suitcase by technicians all over the world.

- The onsite crankshaft grinding polishing machine is ideal for grinding and polishing of main engine and auxiliary engine on board the vessel. All popular make of engine crankshafts can be repaired like MAK, MAN, Wartsila, Daihatsu, Ruston, Yanmar, Mirrless Blackstone, SKODA, etc.

- Onsite crankshaft polisher machine supplied all over the world including Nigeria, Dubai, Singapore, South America, Italy, Maldives, Indonesia, Bangladesh, etc.

For more information on crankshaft polishing machines, crankshaft repair, grinding of crankshaft, and crankshaft polishing tool please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.