RA Power Solutions undertakes onsite crankshaft grinding and repair, crankpin reconditioning, and crankpin machining up to a diameter of 700 mm. It is observed that due to serious accidents sometimes the radius fillet of the crankpin or main journal is damaged and it is difficult to undertake the crankshaft repair onsite without removing the crankshaft from the engine block and transporting it to the designated workshop.

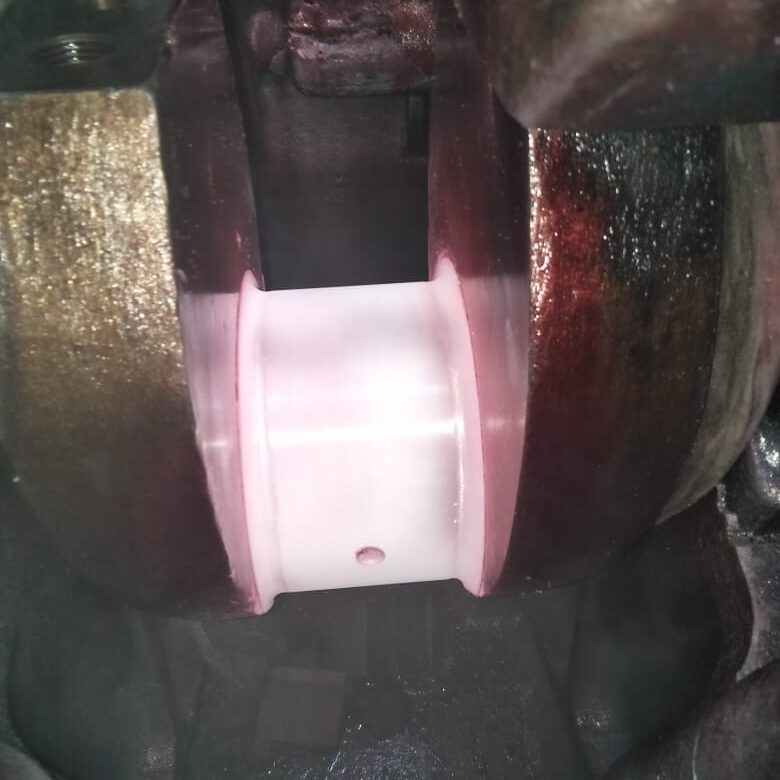

With more than forty years of experience in this field, we have added a portable onsite crankshaft grinding and polishing machine which can undertake crankshaft grinding and crankshaft polishing without taking the reference of radius fillet of the crankpin or crank main journal thus saving the crankshaft from rejection.

It is our experience that the cost of the crankshaft is very high, and in the case of high-capacity engines it works out to be 20 to 25% of the cost of the engine. Considering this fact, it is most important that the job of crankshaft grinding and crankshaft repair is entrusted to the company which has experience in repairing the crankshaft successfully. With the experience of four decades in this field and successfully repaired more than 10,000 crankshafts, we are considered to be leaders in this field and are trusted by the shipping companies, diesel power plants, and engine manufacturers for repair of crankshaft strictly as per the specifications and tolerances stipulated by the manufacturer.

The timely inspection and repair of the crankshaft are again of great importance. We have a team of engineers who can fly on short notice for the inspection and repair of the crankshaft to any part of the world. The crankshaft repair undertaken by us is guaranteed satisfactory performance.

Our crankshaft grinding services have the following features:

- Onsite machining, grinding, and polishing of crankpins up to 700 mm.

- Onsite machining, grinding, and polishing of all cylindrical shafts including turbine, alternator, pump shafts, and tail shaft up to the diameter of 700 mm.

- Repair of radius fillet by grinding and polishing.

- Portable pneumatically, lightweight crankshaft grinding machine which can be taken to any site all over the world.

- All technicians having valid CDC can sail on the vessel.

The author of the blog is Mr. Raj Shahani, Managing Director of the company. He is having 40 years of experience in providing services related to engine repair and overhauling, crankshaft grinding and polishing, crankpin reconditioning, crankshaft repair, and many more.

Contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383 for more information.