RA Power Solutions

RA Power Solutions is a service provider that facilitates power plant operations like Turbine Shaft Repair, Rotor Shaft Grinding, Rotor Shaft Repair all over the world to minimize the downtime.

Onsite repairs and grinding of Rotor shaft, Alternator Shaft and Turbine Shaft is executed in place which eliminates downtime associated with the dis-assembly, transportation and re-installation of the equipment.

Our operations are spread all over the world and our Clients consider RA Power Solutions as a real “Solutions” driven partner in avoiding financial loss when the accident occurs.

We have experience of over three decades in insitu grinding and repair of Rotor shaft, Alternator Shaft, Pump Shaft and Turbine Shaft. We have provided our services to the reputes companies based in Qatar, Dubai, Maldives, Nigeria, Sri Lanka etc.

Services Satisfaction

- On site Crankshaft Grinding

- Crankshaft Grinding Machine

- Connecting Rod Repair

- In situ Metal Stitching and Metal Locking

- Rebabbitting of Bearing

- Second Hand Crankshafts

- Diesel Engine Spare Parts

- Turbine / Alternator Repair

- Rotor Shaft Grinding

- Onsite Rotorshaft Grinding and Polishing

- Repair and Grinding of Crankshaft

- On site Crankshaft Polishing

Crankshaft is one of the important part of diesel engine. It is very important that the crankshaft should be checked periodically for any damage or development of taper and ovality.

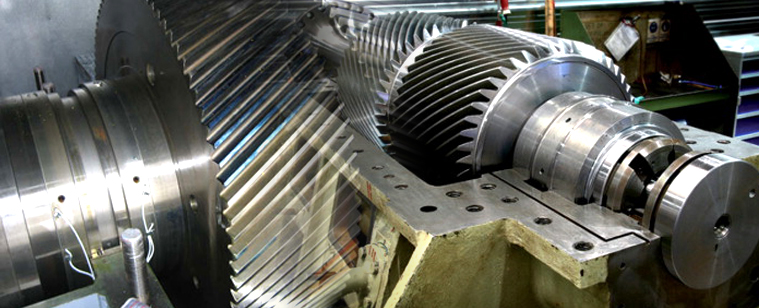

RA Power Solutions undertakes onsite repair and insitu grinding of crankshaft, rotor shaft, turbine shaft alternator shaft and pump shaft. We have latest breed of crankshaft grinding machine. The onsite crankshaft grinding machine is portable and easy to carry to the site. We can undertake onsite crankshaft grinding, rotor shaft grinding, turbine shaft grinding, pump shaft grinding and alternator shaft grinding diameter ranging from 40mm to 700mm.

The insitu crankshaft grinding is done by maintaining the specifications as stipulated by the engine manufacturer. We have experienced team of technicians who are trained to undertake onsite crankshaft grinding, rotor shaft grinding, turbine shaft grinding, pump shaft grinding and alternator shaft grinding.

We at RA Power Solutions stand guarantee for the performance of crankshaft. All the quality control check pertaining to dimensions, cracks are undertaken by our own in-house team of technicians. This ensures the high quality repair of crankshaft, alternator shaft, rotor shaft, turbine shaft and pump shaft.

We provide services to the reputed companies based in Qatar, Dubai, Maldives, Nigeria, Sri Lanka, Bangladesh and Greece, etc.

RA Power Solutions has more than 36 years of experience of grinding and polishing of crankshaft, turbine shaft, rotor shaft, alternator shaft and pump shaft. Portable, light weight grinding and polishing machine has been developed which can be easily carried to the work site. Crankshaft grinding machine has the following features:

- Grinding machine has range starting from 50 mm to 700 mm in terms of shaft diameter.

- Revolutionary grinding equipment developed and manufactured first time which can undertake grinding as well as polishing in very less time.

- Accuracy of 0.02 mm in terms of taper and ovality can be achieved.

- Light weight, easy to carry to work site.

- Highly recommended equipment for maintenance and repair of workshop, power plant and engineering companies.

- Custom made as per clients requirement.

- Economically priced. Over 50 machines sold worldwide.

Connecting rod needs inspection periodically. It is observed that big end and small end of connecting rods develop taper and ovality. RA Power Solutions undertakes repair of connecting rod strictly as per the manufacturer’s specifications and tolerances.

The successful connecting rod repairs undertaken by RA Power Solutions avoid replacement of connecting rods thus saving considerable amount to the owner. We have DRDO equipped vertical boring machine on which connecting rods are repaired for taper, ovality and straightness between small end bore and big end bore. Replacement of small end bush is also undertaken.

In case of excessive wear and tear or damage to the big end bore than the specified limits, the big end bore is rebuild and machined to the standard size with guarantee.

Cracks in cast iron are developed due to excessive stress beyond its tensile strength or due to accident. The heat related cracks and cracks due to impact are quite common in case of engine blocks, casing of turbo charger, compressors and mechanical equipment.

The repair of cracks in cast iron has been tried by the different process and methods especially in case of cracks in the engine blocks. The welding process for the repair of the cracks is not always successful due to excessive heat generated. It is observed that even the center line of main journal housings gets disturbed and looses alignment.

RA Power Solutions undertakes repair of cracks by cold process i.e. metal locking and metal stitching. The metal lock and metal keys are sourced strictly as per the metallurgy of the broken casting and are inserted in a specific process.

It is observed that the repair of cracks by metal stitching process is successful in comparison to conventional welding method.

Onsite metal locking and metal stitching is done by our skilled engineers. This is of great advantage to the end user as it reduces the downtime.

RA Power Solutions have more than three decades of experience in undertaking repair of cracks by metal stitching process. Repair of following damaged castings have been successful undertaken.

- Metal stitching of engine block (Wartsila, MAN, Mirrlees Blackstone, Daihatsu).

- Repair of turbine casing of turbo charger.

- Onsite repair of pump casing by metal locking.

- Metal stitching of forging press.

- Metal locking of cracked cement, power, chemical, sugar plants machinery.

We undertake onsite grinding of turbine shaft up to the diameter of 700mm. The tolerances of turbine shaft after grinding and polishing are maintained strictly as per the manufacturer’s specifications. We manufacture new white metal turbine bearings as per the samples or drawing. Rebabbitting of old bearings is also undertaken. We use the high quality of white metal for rebabbitting. RA Power under takes Rebabbiting of white metal bearings by centrifugal process.

Crankshafts of most popular manufacturers of engines are available. The used crankshafts are sourced from different ship breaking yards, diesel power plants which are either replaced by turbines or are not used due to availability of Grid power. The used crankshafts are brought to our factory and thoroughly examined and are calibrated for taper, ovality, surface roughness, hardness, cracks, etc.

The crankshaft is reconditioned and main journals and crankpins are polished and it is our endeavor to maintain the tolerances as per the manufacturers recommendations after the crankshaft is refurbished. The used crankshafts are supported with calibration report. The second-hand and refurbished crankshafts are competitively priced.

We have following reconditioned crankshafts of different makes available in stock:

MAN-B&W, Sulzer, Wartsila, Mak, Deutz, Mitsubishi, Caterpillar, Daihatsu, Bergen, Niigata, Himsen, Allen, Stork, Fiat, MWM, Hanshin, SKL, Ruston, Paxman, Crepelle, Yanmar , Mirrlees, Alco, ABC, Crepelle, Pielstick, Nohab etc.

RA Power Solutions supplies spare parts of high capacity diesel engine. Following are the major spare parts available:

- Piston Rods

- Camshafts

- Cylinder Heads

- Connecting Rods

- Cylinder Liners

- Crankshafts

- Complete Auxiliary Engines

- Engine Frame and Bedplates

- Fuel Pumps

- Pistons

- Various Other Parts

The spare parts of MAN-B&W, Sulzer, Wartsila, Mak, Deutz, Pielstick, Mitsubishi, Nohab, Daihatsu, Yanmar, Bergen, Crepelle, Niigata, Himsen, Allen, Stork, MWM, Hanshin, Caterpillar, Ruston, Paxman, Mirrlees, Alco, Fiat, ABC, Crepelle, SKL, etc. are available in stock.

Used and reconditioned spare parts are supplied supported with calibration report and guarantee.

Recently, diesel generators of high capacity are replaced by turbines. Although the cost of turbine works out to be higher than the cost of diesel generator sets. But due to the low running cost the turbines are getting popular and are installed in India and developing countries.

RA Power Solutions provides onsite repair of rotor shaft, alternator shaft, and turbine shafts. We have facility of onsite equipment ready to undertake grinding of rotor shaft, turbine shaft, alternator shaft and crankshaft having diameter ranging from 60 mm to 700 mm. The portable turbine shaft grinding equipment is taken to the site and grinding of turbine shaft is undertaken as per the tolerances specified by the turbine manufacturer. RA Power Solutions is extending the services of onsite grinding, polishing and inspection in India and all over the world. The white metal bearing are also manufactured as per the diameter of rotor shaft, turbine shaft and alternator shaft maintained after onsite grinding. The rebabbitting of old bearings is also undertaken.

In case of any breakdown we also offer metal stitching and metal locking services for crack repair of turbine casing. RA Power Solutions has executed more than 300 jobs of turbine repairs during their working of three decades.

Rotor Shaft Grinding In industry and power generation plant turbines are running continuously. The rotor shaft which is supported on white metal Babbitt bearing gets worn out developing taper, ovality, bearing line marks and damage to the white metal Babbitt bearing.

RAP undertakes on site repair of rotor shaft bearing sitting diameter. There is no requirement of disassembly of rotor shaft. The rotor shaft diameter is dimensionally checked by experienced engineers. The hardness and crack detection test is also undertaken which is of great importance. The grinding of rotor shaft diameter is undertaken by portable rotor shaft grinding machine. The tolerance within 20 microns is achieved with a requisite surface finish. We have facilities to undertake rotor shaft grinding and polishing up to 700 mm diameter. We work in two shifts of 12 hours each to reduce the downtime.

We also design and manufacture rotor shaft grinding machine as per site requirement up to 700 mm and have sold more then 60 machines all over the world.

In case of a turbine the rotor shaft is an important part which is forged steel as per the designing parameter of the main equipment. The periodical inspection of rotor shaft mainly the bearing sitting area is of great importance. It is observed that the surface roughness or line marks are developed. In certain cases taper and ovality also increases. RA Power Solutions extends services for onsite polishing of rotor shaft. The polishing is undertaken by light weighted, portable rotor shaft grinding and polishing machine. After polishing the bearing line marks, pitting and the rough surface are removed provided the diameter remains within the tolerances.

RA Power Solutions undertakes onsite grinding of rotor shaft up to 700 mm in diameter. The process of onsite grinding and polishing of rotor shaft is successfully proven. We have executed more than 800 jobs of onsite repair of rotor shaft worldwide.

RA Power Solutions design, develop and manufactures onsite rotor shaft grinding and polishing machine. These grinding and polishing machines are very easy to operate and are competitively priced. We also extend on job training to the client.

RA Power Solutions Pvt. Ltd. has more than 37 years of experience of successfully executing repair of crankshaft irrespective of type of damage it has. The repair of crankshaft in most of the cases is done onsite.

We have state of art crankshaft grinding equipment which is portable and light weight and can be carried to the site. More than 1100 jobs for repair of crankshaft up to 700 mm diameter have been executed.

RA Power Solutions Pvt. Ltd. also sells onsite crankshaft grinding machine which is easy to operate.

Crankshaft is an important part of diesel engine. It is generally observed that after running for considerable hours, surface roughness, bearing line marks or pitting is observed on the main journal and crankpin of the crankshaft. The reason for development of rough surface can be

- Use of Substandard Lube Oil

- Presence of Impurities

- Poor Maintenance, etc.

In this situation RA Power Solutions recommend polishing of crankshaft. Following steps are suggested:

- Calibration of main journal and crankpin is done to check the dimension, taper and ovality.

- Magnetic particle test is done to rule out any possibility of surface cracks.

- Checking of hardness is done to identify hard spots if any.

- Visual inspection to check the profile of radius fillet and lubricating oil.

In case above parameters are observed within the limit polishing is suggested.

RA Power Solutions has developed centre less, easy to operate, portable onsite polishing machine which can undertake the polishing without dismantling of the shaft. The job of onsite polishing is executed by experienced technicians. Surface finish and other technical parameter are maintained as per the specified stipulated by manufacturers.

About Us

RA Power Solutions Pvt. Ltd. strongly believes that by paying attention to even the minor aspects involved in rotor shaft, crankshaft, alternator shaft and turbine shaft results to the successful performance of the equipment after repairs.The selection of grade of white metal, proper bonding, and process are the areas where the attention is paid to ensure that the repairs are as per the manufacturer specification. The designing of portable equipment used for grinding of rotor shaft, crankshaft, alternator shaft and turbine shaft is done in a manner that the results obtained after grinding and polishing in terms of taper and ovality are as per the tolerance stipulated by the manufacturer. The attention is paid to maintain the tolerances as close to 10 microns depending on the diameter of the shaft.

I have worked with several service providers in last 40 years and can unequivocally say that RA Power Solutions is the best in terms of service and punctuality. Today, it is the only company which executes repair of turbine shafts, supplies the white metal bearings and stands the guarantee for the satisfactory performance.

Author: SAMUEL ALEXANDER, Sudan

Grateful to Raj and his team for extending their support in repairs of major components of a power plant having capacity of 123 MW. The parts supplied are of OEM standards and our company have saved substantial amount by taking his service and spares.

Author : Maria Clara, South America